Doc's Anything Goes

Currently Offline

Posts: 1,226

Likes: 81

Joined: Apr 4, 2014 3:52:42 GMT -6

|

Post by richardv on Aug 9, 2014 17:55:12 GMT -6

Sounds like your a chocoholic as well.  That radiator looks a bit large for it but, a small heater core could be placed behind the license plate. I've seen this done on a cars front plate. But ours are larger than cycles plates. |

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Aug 9, 2014 21:00:55 GMT -6

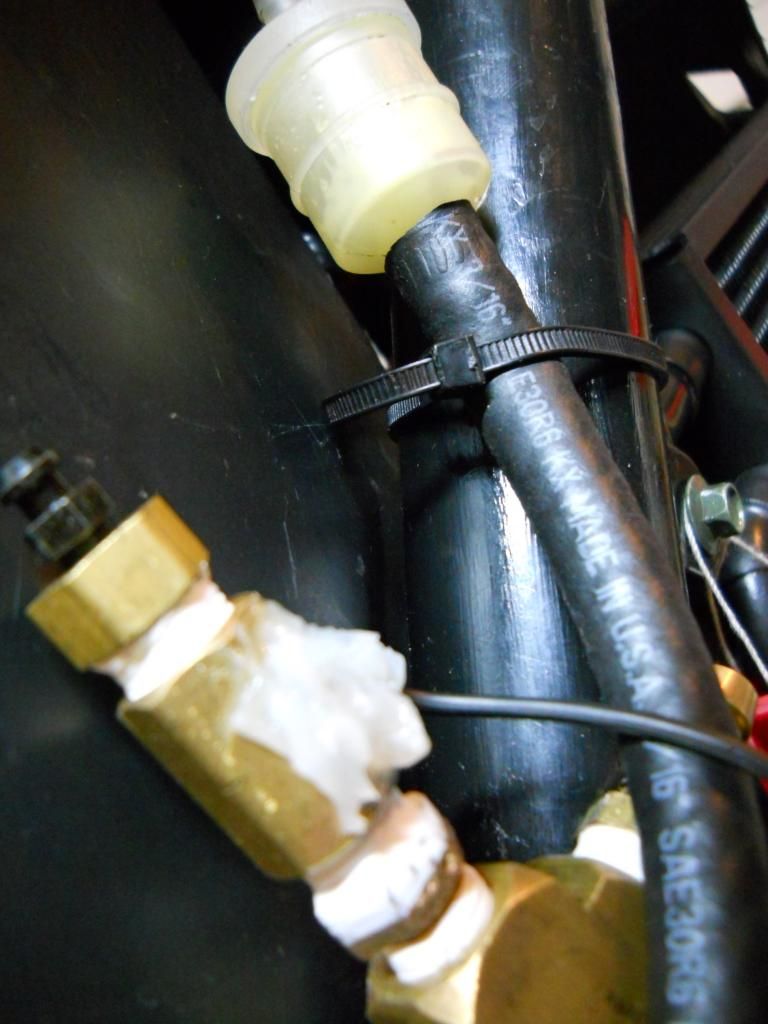

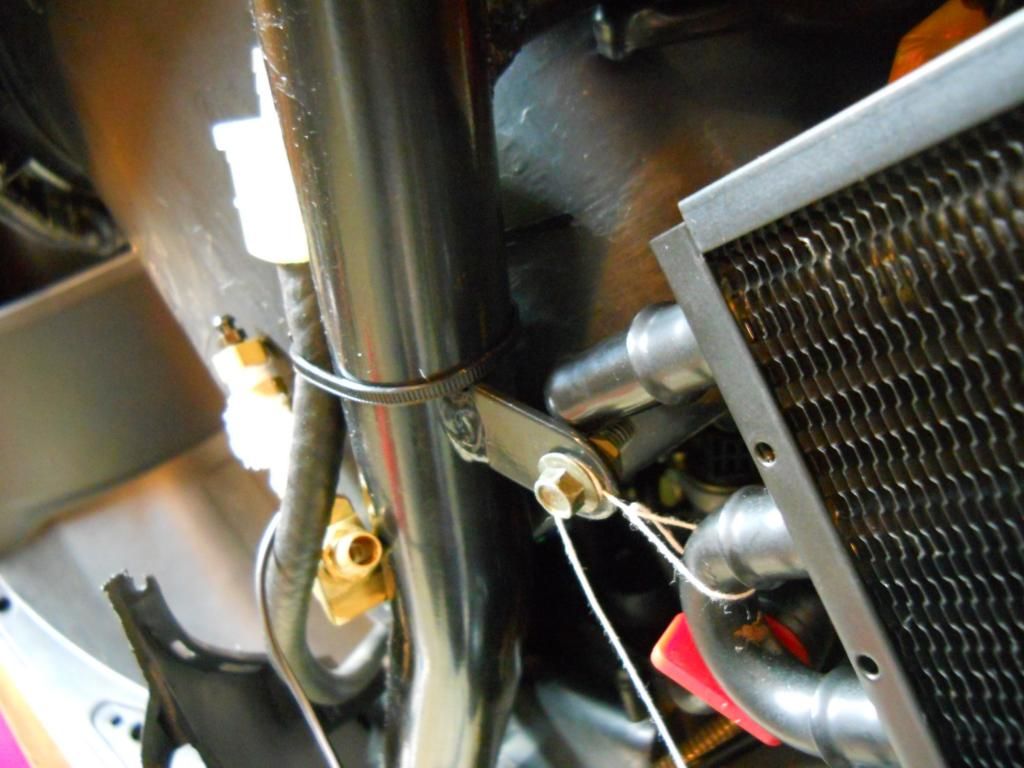

I think my cat wanted to help me today... or she wanted me to stop working on the scooter and pet her.  I started by installing the pod filter to see if I could get the engine running satisfactorily with it and thus give me more room to mount the radiator by removing the stock airbox. I up-jetted the main to 88 from 85, the idle jet from 34 to 35 and moved the needle clip down two places. As I was taking the jets out a voice in my head told me to look at the accelerator pump, so I did (I never argue with the voices in my head, they can kick my butt from the inside). I'm glad I listened to that voice; the diaphragm appeared to be too big for the machined out hole for it. Luckily I had a spare accel. pump diaphragm from the carb that came with my scooter form the factory, it fit much better than the other one:     As you can see the smaller diaphragm fits much better. I reassembled the carb and started the engine. WAY too rich. I think the engine was only firing every other power stroke at idle, plus I think I fouled the spark plug:  I put the 34 idle jet back in, moved the needle clip up one place, and replaced the old autolite plug with an NGK. Much better. I dialed in the idle adjust screw and went for a ride. The engine ran just as good as it did with the stock airbox, maybe even better, but man that pod filter is loud! The oil temp got up to 99c (210f) and according to the chinese tach the engine goes to 8k rpm at launch, down to 7.5k under WOT acceleration and back up to 8k at top speed. I got back to the garage and rerouted the fuel lines:   I noticed that since I unhooked the valve breather hose from the air intake, attached a filter, and zip-tied it to the frame, quite a bit of... stuff has accumulated in it:  Oh well, the airflow is unobstructed and oil isn't coming out of the other end of the filter so I'll let it be. After I let the engine cool down I took the valve cover of and mocked up locations for the "add-a-drain" starting with the top as recommended by Bashan.    It would be an incredibly tight fit and I would have to cut away part of the bucket seat for it to fit. However, if I put it on the side...    There is lots of room for the plug and the elbow+hose barb fittings. Unless bashan or anybody else objects to that location for any reason, I think I'll mount it there. I started mocking up locations for the radiator again, keeping in mind I have to mount it to the frame OR the engine. Here is what I came up with:  The left red lines I know I am going to use, the right red line is one option for mounting, the blue is another. Both mounts will be behind the radiator; I am going to build an air scoop for the front. As far as the 4-way fitting, I still don't know how or where I am going to mount it. The darn bucket seat is in the way again:    I'm really starting to think that making a metal frame to support the seat and cutting out the bucket part would be a good idea. I have some scrap metal, but not enough to make a complete frame:  Alas, there comes a problem with that. I had an unexpected $155 expense and I had to tap into the scooter fund, leaving me with little reserve for scooter-related expenses. Also, I am running quite low on PLA (PLA is the kind of plastic my 3d printer uses). I'll go to home depot tomorrow and price-out the pieces of metal I think I'll need for the seat frame and radiator mounts plus some rivets (I do have a welder, but it is only a little 80 amp buzz box with 4 or 5 year old electrodes, and I'm not too good at striking an arc or welding in general). If I do make the metal frame, I'll have to hope that nothing else happens that'll cost me money (murphy's laws are screaming at me right now; anything that can go wrong, will go wrong), or that I will run into some more money. At any rate, I'm still going to continue with this project and eventually with the arduino-tachometer project. Lets end this post on a lighter note: Kitty!  |

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Aug 9, 2014 21:13:48 GMT -6

Sounds like your a chocoholic as well.  That radiator looks a bit large for it but, a small heater core could be placed behind the license plate. I've seen this done on a cars front plate. But ours are larger than cycles plates. Recently, as in about 2 months ago, I stopped drinking all soda/pop and eating sweet sugary stuff. I've already lost some weight. The brownies were for my mother. I did look into a smaller radiator extensively, but it would have actually cost more for a smaller one. One about half the height the one I have would have been $40-$60 and I couldn't find a heater core in good enough condition, the right size, and at the right price. Also, all the fuel line to mount the cooler in the front of the scoot would have cost more. |

|

|

|

Post by Bashan on Aug 9, 2014 21:55:59 GMT -6

The side of the cover is fine, I was just spit balling. If the bucket is in the way and you're short on funds, a temporary fix might be to put the valve INSIDE the bucket until funds or the muse guide you elsewhere. Fit it up through the access panel as you lower the seat into place. I'm just spit balling. Pa-tooo! OW! You little jerks!

|

|

Doc's Anything Goes

Currently Offline

Posts: 1,226

Likes: 81

Joined: Apr 4, 2014 3:52:42 GMT -6

|

Post by richardv on Aug 10, 2014 6:54:36 GMT -6

I hear ya about tight funds but don't skimp on the mount. Both the upper ideas (red & blue) should be used together. The tri-angulation will give the strength needed or it will eventually fail due to vibration. I'm new to scooters so I can't give advice on the other issues.

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Aug 10, 2014 7:17:14 GMT -6

I would like to keep the 4-way as the highest point in the loop without any dips between it and the radiator to let all the air get to the bleeder valve as easy as possible, but thanks for the idea!

Good idea with the combined radiator mounts. I do have one smallish sheet of .050 inch metal, but that is too thin and would just flex instead of holding the rad. I could triangulate it and/or use two layers of it...

I'll go to the local flea market and see if I can get any scrap metal and try not to buy anything I don't immediately need. If I don't find any there, then I'm off to home depot.

|

|

|

|

Post by cyborg on Aug 10, 2014 9:09:34 GMT -6

Do not overlook tubing as a mounting material,,,it is very inexpensive and also very strong and easily bendable to make shapes and also i use a vice to create flats that can be drilled for mounting,,,some small oil cooler and gauge i mounts made out of tube looked stock,,,and were very strong rivaling oem

|

|

|

|

Post by cyborg on Aug 10, 2014 10:13:46 GMT -6

Oh as a side note if you dont have a tubing bender that has the radius you need,,,cut the tube to approximately the length you need plus a little,,,, tape one end with good quality duct tape fill the pipe with fine sand then tape the other end you can bend the tube this way and it will not kink,,,

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Aug 10, 2014 14:17:55 GMT -6

Oh as a side note if you dont have a tubing bender that has the radius you need,,,cut the tube to approximately the length you need plus a little,,,, tape one end with good quality duct tape fill the pipe with fine sand then tape the other end you can bend the tube this way and it will not kink,,, WOW! that is an awesome way to do that. I just bought 4 ft of 3/4" x 1/8" angle iron, 3 ft of 3/4" x 1/8" flat steel, and some steel rivets. If it turns out that I can't make what I want with this, I'll return then and get something else. Unfortunately, my home depot and menards only sells flat, sheet angle, square, rod, and all-thread stock metal; no tubing. But seriously, thank you for that way to bend pipe. It is information sharing like that that makes this forum awesome! I'm off to sketch-up a seat supporter and rad mounts. On a side note, it I wear some medical/latex gloves, will that help prevent the oils from my hands getting on the metals and start rusting? These home improvement stores can be real picky about returned metal stock. |

|

|

|

Post by cyborg on Aug 10, 2014 14:41:38 GMT -6

They do indeed sell tube stock,,, think electrical conduit,,, BAM!!!!

|

|

Doc's Anything Goes

Currently Offline

Posts: 1,226

Likes: 81

Joined: Apr 4, 2014 3:52:42 GMT -6

|

Post by richardv on Aug 10, 2014 16:59:16 GMT -6

My local hardware will sell smaller lengths of electrical conduit and it is quit strong and easily worked. It can be cut to length with a hack saw or tubing cutter with patients.

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Aug 10, 2014 18:23:05 GMT -6

Turns out the length of angle iron I bought was too short for what I needed, I also found 4x 1ft pieces of flat 1"x1/8" painted iron from a swing I refinished a while ago, so I can return the length of flat iron and angle iron I bought and just buy a bigger piece of angle iron.

I apologize, you were correct; they do sell metal tubes. But I already have rough plans for using angle iron. I'm not trying to say that the seat frame cannot be made with tubular metal or that you are blatantly wrong; I just already had plans for angle iron.

This time I bought 6' of 1" x 1/8" angle iron for $10 minus an 11% rebate. I'm pretty sure that will be enough and then some, but before I start cutting any metal, I'm going to make a mock-up using cardboard and/or wood to make sure I have every length, angle, and shape correct so I don't waste any metal stock.

Oh and the latex gloves were a crap-shoot. I forgot I have Hyperhidrosis and within minutes my hands were wrinkled as raisins.

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

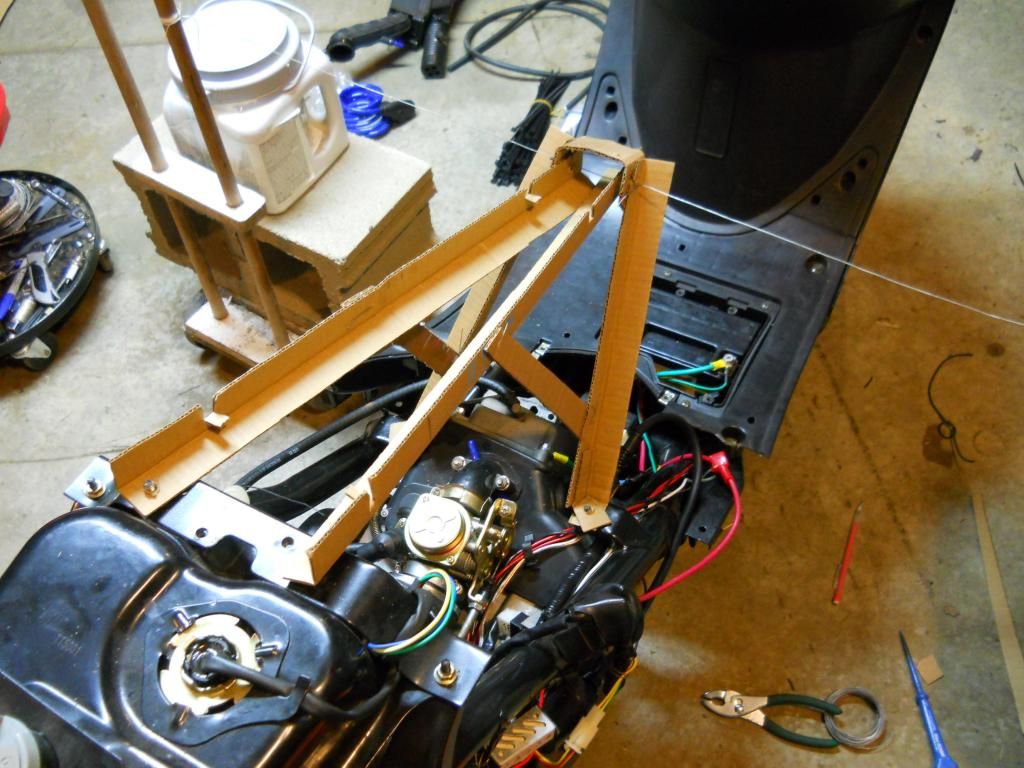

Post by glavey on Aug 10, 2014 20:16:53 GMT -6

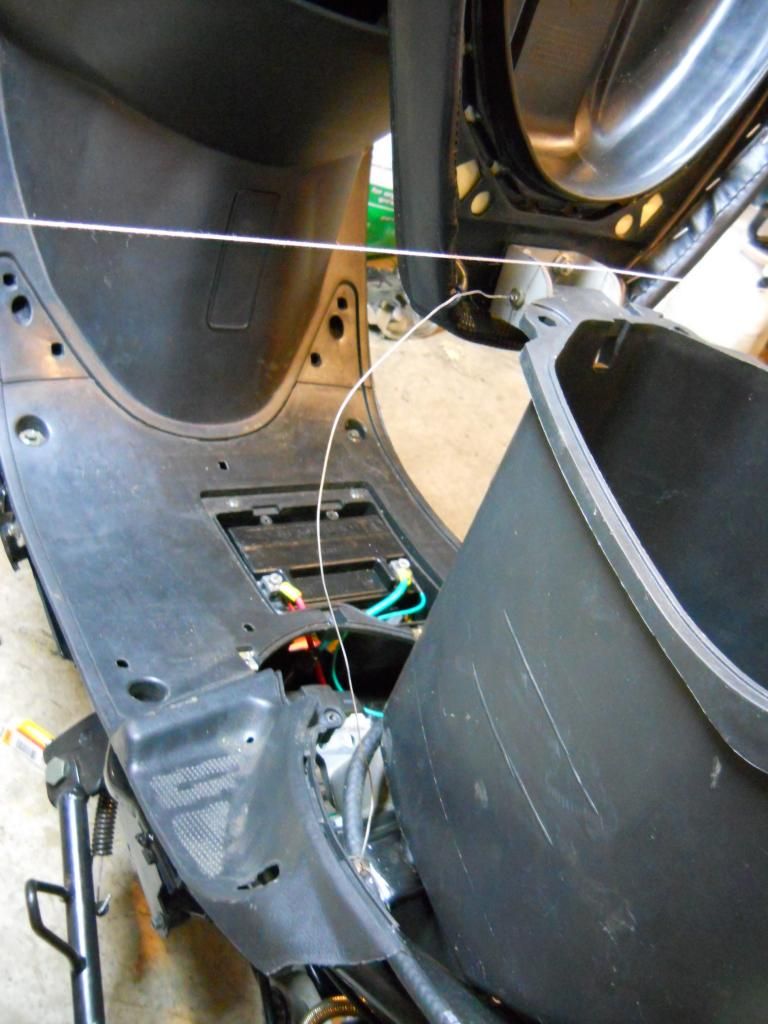

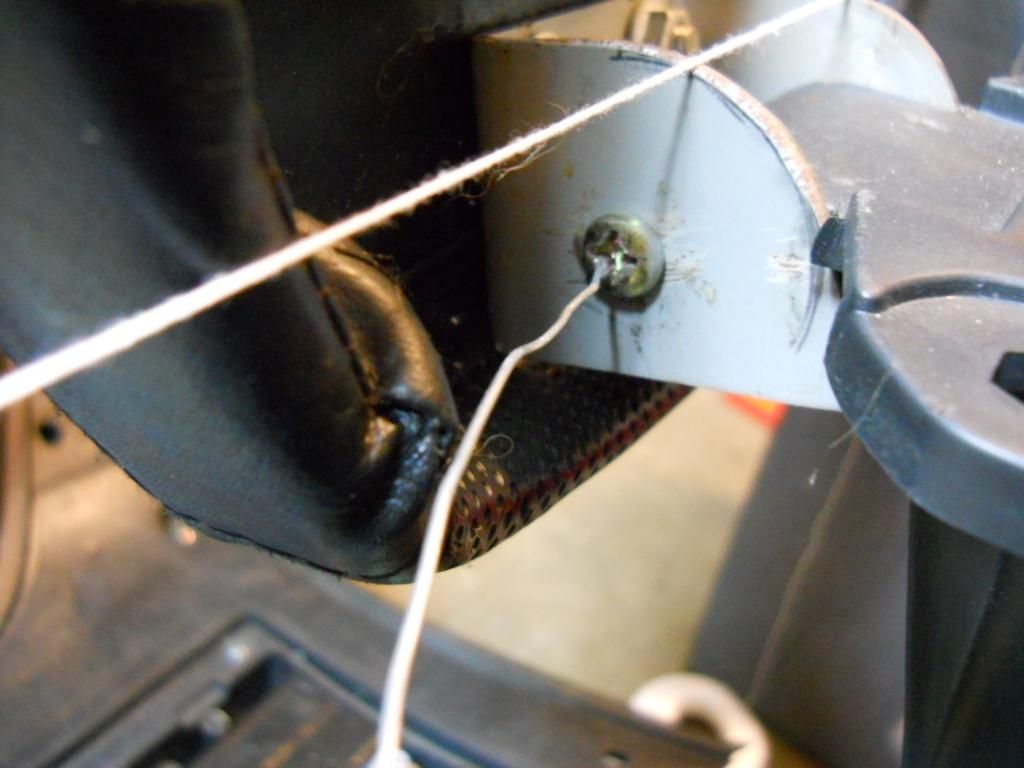

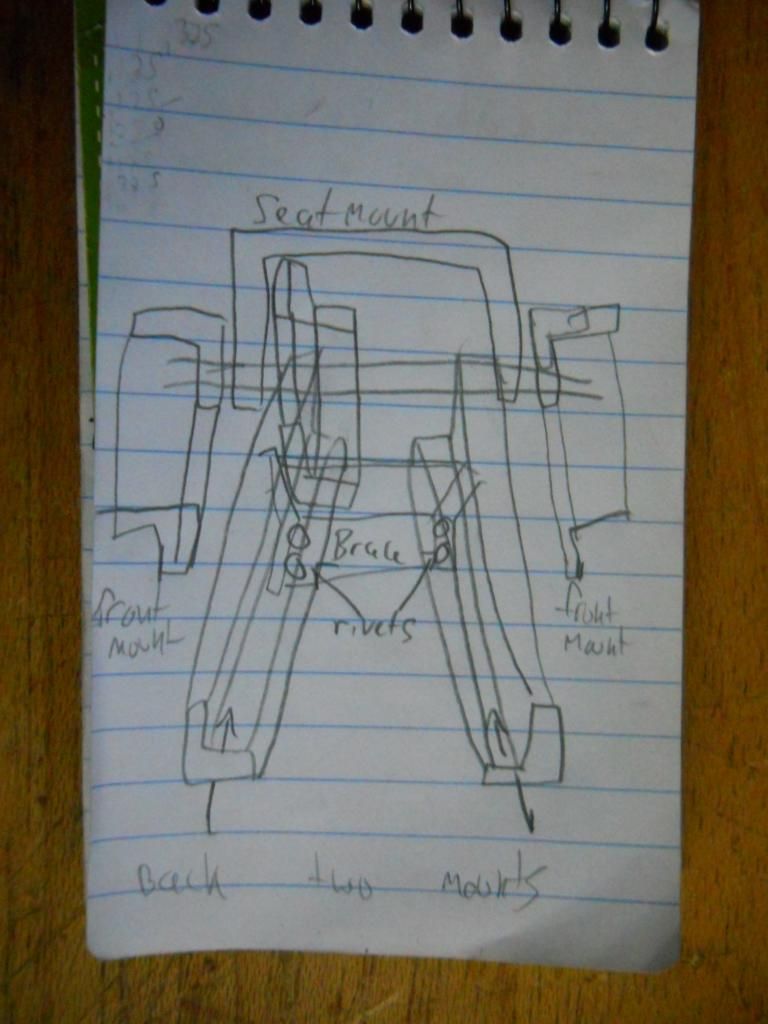

lets start off with an inventory of power tools I have at my disposal. I am not trying bragging at all; every one of these except the dremel was inherited or given to me as a gift. Old washing machine (or it could have been a dryer) motor turned into a grinder:  An incredibly old bench grinder made by k-mart. Do you even remember when k-mart made their own power tools?  Skill/jig saw, given to be as a birthday present from the same person I inherited most of these tools from.  A fisher-price quality drill given to me by a family member that didn't know me very well.  I do have other better black and decker drills, but the charger took a crap a few years ago and it seems no one has a charger for ni-cad drill batteries anymore, it's all li-ion and li-po. My dremel with assorted bits and a routing attachment.  A couple abrasive cut-off disks that fit (kinda) on the dryer motor-turned-grinder.  A good old hack saw, of which I have quite a few. I seem to have lost or misplaced the blades.  And finally a riveting gun.  Again, I am NOT trying to brag at all, I am just showing what I have to work with. Here is the pieces of metal I bought at first:  But then I realized that I would need more angle iron. Also, I found 4 pieces of painted flat iron that were left over from a swing I refurbished for my mother. They were the exact same thickness and two of them equaled the length of the flat iron I had bought, and there were 4 of the painted pieces so I could return both the angle and flat iron and buy just one longer piece of angle iron. I ended up getting a 6' x 1" x 1/8" angle iron piece for $10 minus an 11% rebate. When I got home I noticed that one of my neighbors was throwing away an old satellite dish and mounting hardware, so I picked it up... because I could. I'll use all of the angle and flat iron first before I think about cutting up the dish; I might be able to turn it into a directional wifi antenna.  I started using string and mechanics wire to help visualize the location of the seat mount point once the seat was removed:      Next I cut up some cardboard to make faux angle iron for the mockup. I wondered my so many mosquitoes were biting me and then I looked out the window: darkness... looked at my watch... oh darn time to retire to the computer for my daily log of activities and blunders. Here is a abysmal, horrid, abomination of a drawing I made to help me remember what I am trying to accomplish. I'm quite sure I have ADD; I always am in the middle of planning something intricate, I figure out one part of it, go on to another part and then I forget the first part I thought of. Writing stuff down for me is essential. I dare you to try and comprehend this!  Hopefully that won't give you nightmares. Toodles! |

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

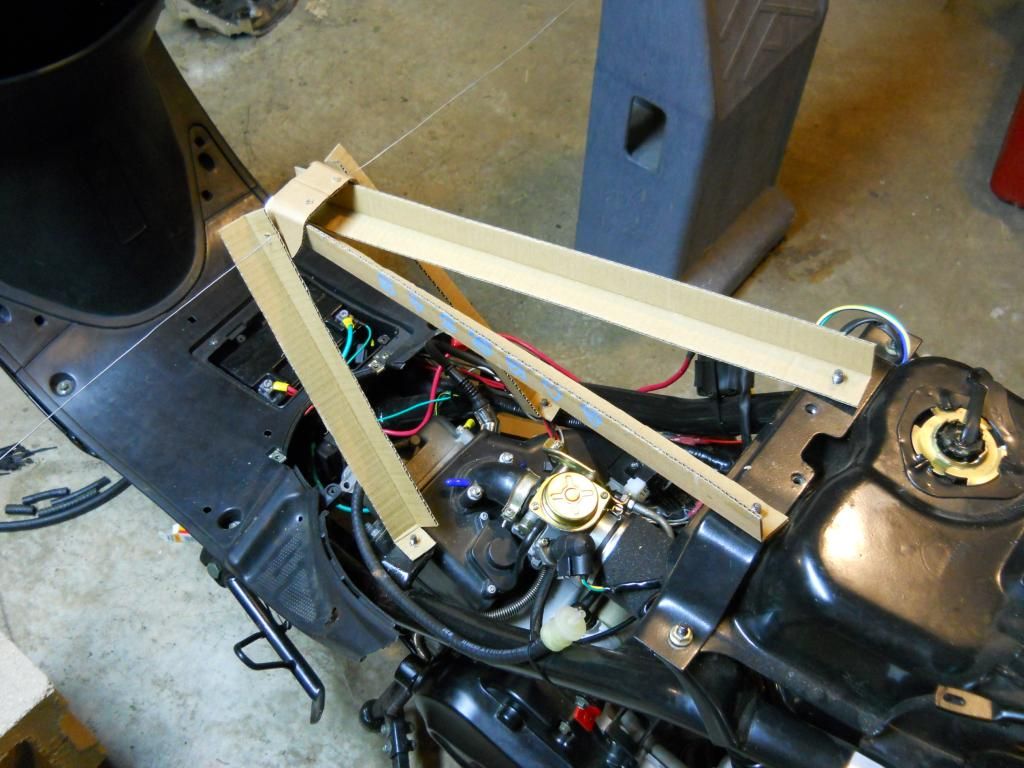

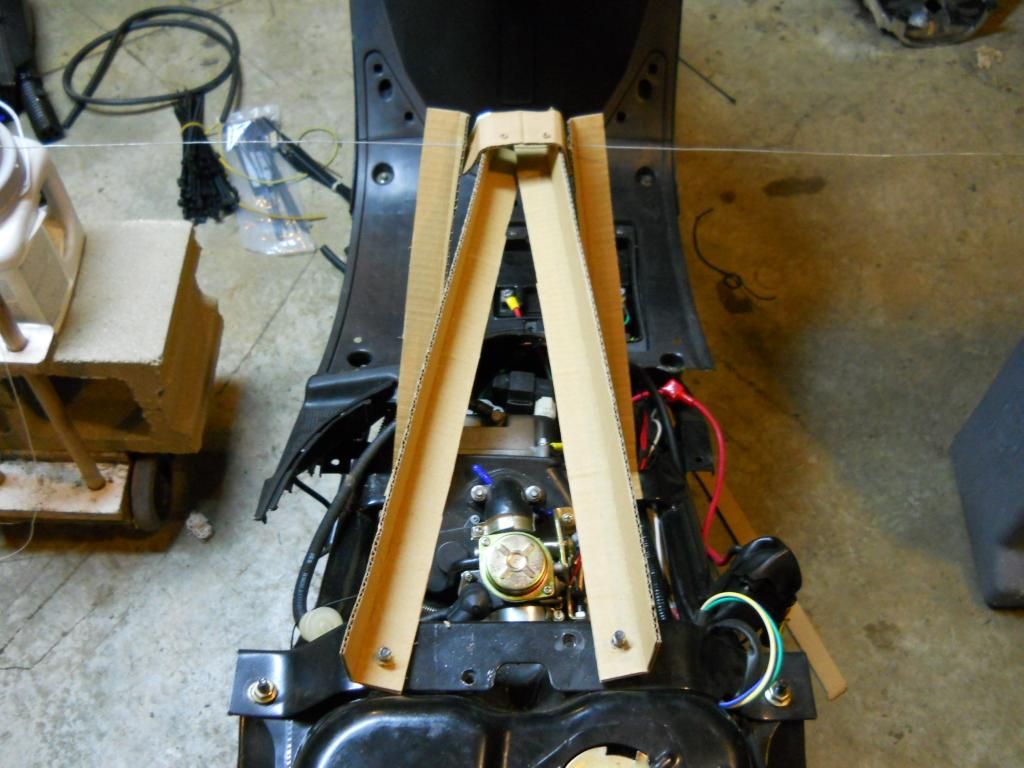

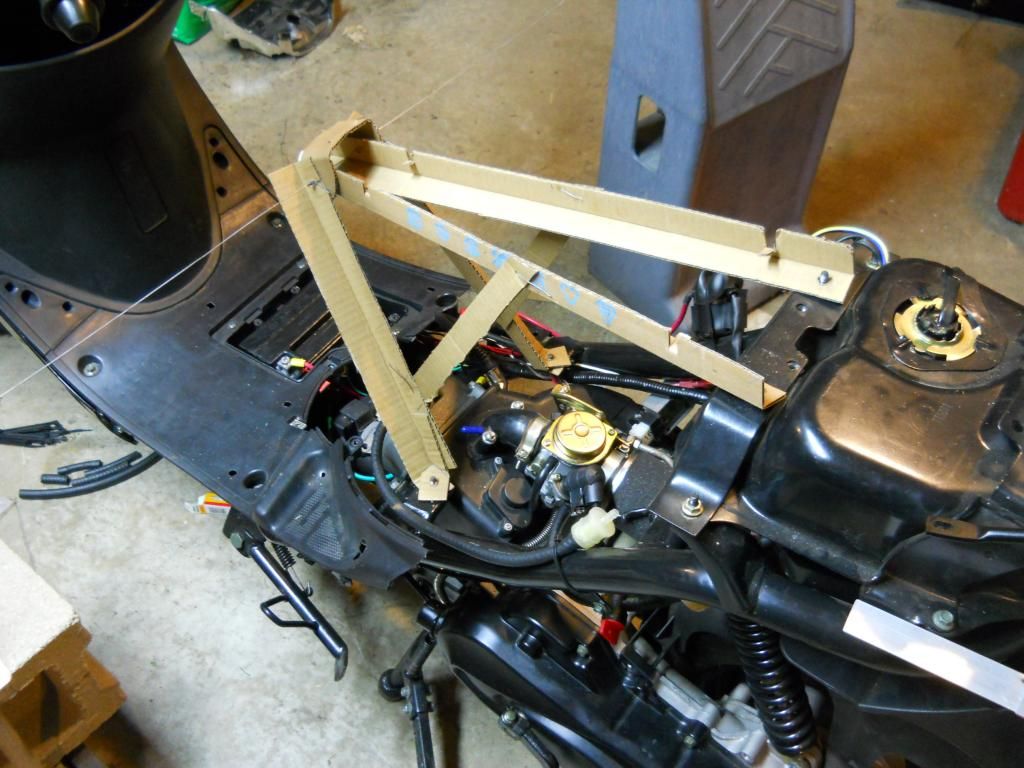

Post by glavey on Aug 11, 2014 9:46:10 GMT -6

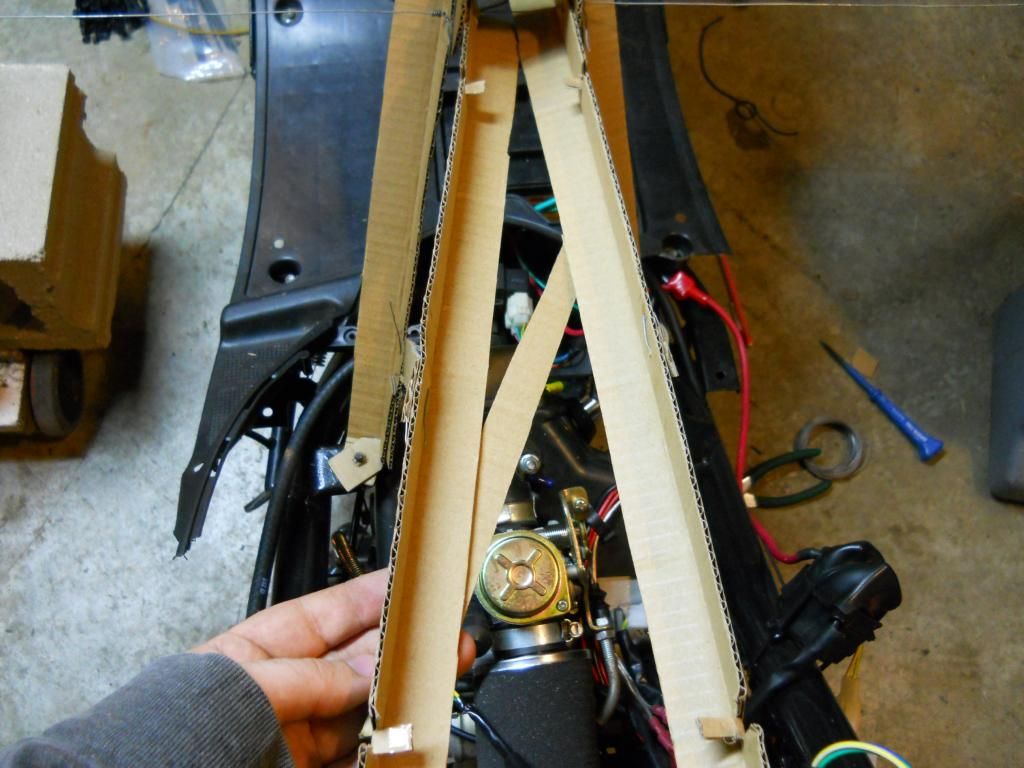

Quick update before I get back out to the garage: Here are some pics of the cardboard mockup:     And here is a piece I had already made for the seat:  It turns out that the county where I live had a water main break, they cannot find it but believe it might be underneath a river, so only essential and minimal water usage and if water supply drops too low, I will have to boil water before it is potable. I still have much reinforcement and triangulation to do with the seat frame. Back to the garage! |

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Aug 11, 2014 12:46:20 GMT -6

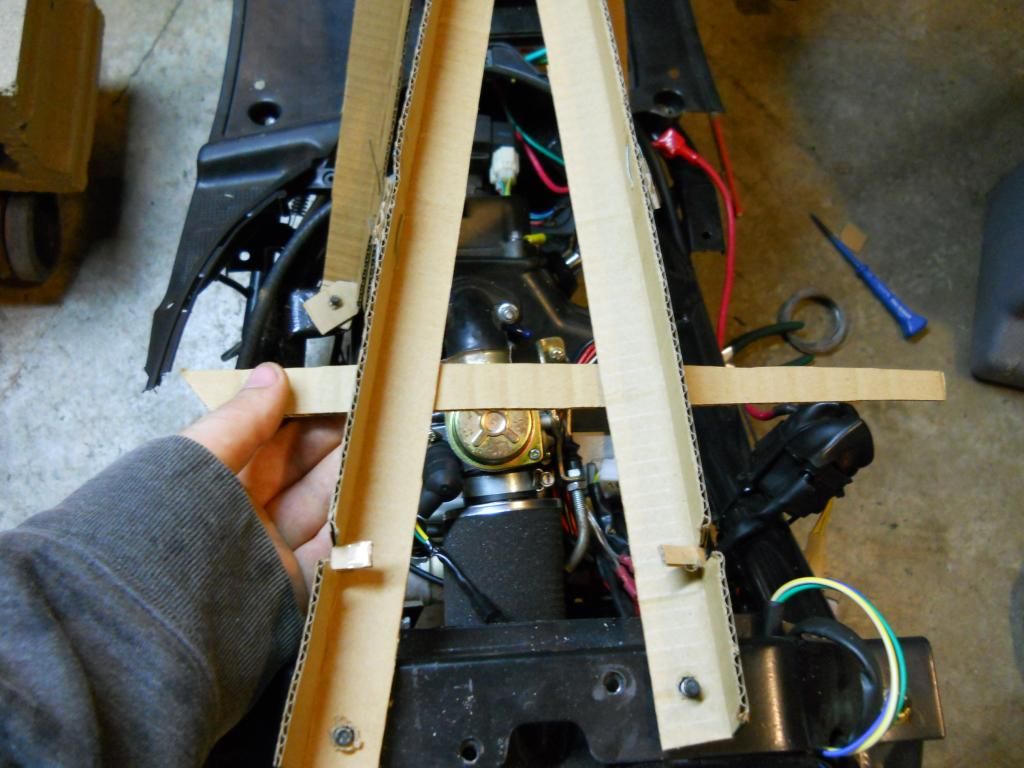

A bit more progress...    Now, as far as triangulation and reinforcement goes, should I do something like this:  Or this:  Its amazing that with just those 4 angled pieces I've already allocated 64 inches of the iron stock. It has started to rain quite heavily here so that'll be it for today. |

|