Post by Alleyoop on Mar 27, 2013 12:32:49 GMT -6

VARIATORS:

A lot of the Performance Variators they sell actually will not get you more top end speed. What most do is keep the weights lower in the ramps for good takeoff speeds and mid-range.

How a Variator will perform depends on how they built it and for what purpose. They do this by changing the angle of the ramps, length of the ramps and the curvature of the face plate where the belt rides on. A steeper ramp will keep the weights in the lower part of the ramp much longer which will give you strong takeoffs and good mid-range speeds. It requires more rpms but your scoot will get from Point A To Point B much quicker. A less angled ramp will go through the gearing ratio very smooth all the way to your top end speed.

Some Variators the ramps are to steep and short that the weights will not move out far enough in the ramps to push the belt as near as possible to the edge of the Variator and you will loose top end speed. This type of variator causes the acceleration not to be a nice smooth progression in speed. Since the ramps are shorter once you get to a certain speed say 45mph to get to 50mph is a slow process.

Some Variators the curvature of the face plate near the edge is to wide and your belt will never be able to get near the edge because the curvature near the edge of the variator is to great to hold the belt there.

So the best Variator must have ramps that are NOT to steep and a good Length along with a Face Plate that the Curvature is not too great so that the belt will move as close as possible to the edge and hold there.

The only ones that really give you more top end which also requires the right weights and rpms are the ones that are Bigger In Diameter than what you currently have on. Also good ramp length and the curvature of the face plate not to pronounced to allow the belt to actually get near the edge and hold. .

Here is what the Bigger Diameter will do. A bigger wheel turning a smaller wheel will turn the smaller wheel faster. So a bigger Variator the belt will climb out further thereby turning the Clutch pulley faster per revolution of the Variator.

And May I add to turn the Variator faster you need more RPMS. So its a combo of things to get the most speed. You can put in the heaviest weights and the belt will get squeezed to the edge of the Variator BUT if the RPMS are low you can actually go slower. So the RPMS have to be enough to keep turning the Variator faster once the belt reaches its highest point. That is why if you notice once you get rolling and the belt is already at its max height, as your RPMS start to climb you are picking up speed. In addition you can actually run out of gearing, what that means is no matter how many rpms your cranking out or the belt climbing to the edge, once you reach the limit of the gearing you will NOT get any more speed.

Here is also a comparsion of a OEM Variator and a PERFORMANCE Variator:

Another thing you can do is cut down the BOSS so that it squeezes the belt more between the pulleys without having to have really heavy weights to move the Variator out as far as possible. This will also give you the option to put in a belt that is NOT as wide as the Original so that it may drop further in the CLUCTH pulley to create a smaller wheel. Remember BIGGER WHEEL WILL TURN a SMALLER WHEEL MORE TIMES per 1 rotation of a bigger wheel.

CVT WEIGHTS:

The engines have pretty good torque have descent power as long as you do not go overboard.

Check your Variator first and see if Both Pulleys are the Same Size.

If the Variator itself is smaller than the Outside Pulley you can get what they call a PERFORMANCE Variator that is the same size as the Outside Pulley.

Belts will only climb as high as the Smallest Pulley.

So by having Equal Size Pulleys the belt now can be made to climb higher for more TOP END SPEED.

Also weights play a major roll on making the Belt climb higher.

Heavier weights Require Less RPMs to push the Belt up the Variator.

Lighter weights Require Higher RPMS to push the Belt up the Variator.

Roller Weights - Will Change your RPMS by 500-600 for every gram up or down.

Slider Weights - Will Change your RPMS by 200-350 for every gram up or down.

What I did is experiment with different Gram Rollers first they are cheap.

When I found the weights that I liked and at the RPMS I liked I then put in Dr. Pulley Sliders and went ONE gram Heavier on the Sliders So my Rpms would be almost the same as with the Gram Rollers I liked. So I gained just a little more top end with the Sliders due to Fact they are 1 Gram heavier than the Rollers and still the same RPMS.

Heavier weights will push the Variator out and squeeze the Belt more so it climbs higher for more top end. BUT to heavy of weights will make your takeoff and Mid-range sluggish.

Also Heavier weights will cause your RPMS to drop so you also have to watch out for that.

You want to run at or Near the RPMS the engine makes its MAX Horsepower. If it revs much higher than that the engine is Not producing any more horsepower and in many causes will loose horsepower due to floating valves etc.

Lighter weights take MORE RPMS to throw out the weights to Push Variator out to push the belt up the Variator. To Light and it will not push the belt as high as possible and you will loose top end but you will have a quicker takeoff and Mid-Range because the belt is staying in the lower gearing of the Variator longer.

CONTRA and CLUTCH PAD SPRINGS:

Stronger Contra Springs effects the RPMS required to OPEN THE CLUTCH PULLEY. The Stronger the Contra Spring the HIGHER RPMS is required to open the Clutch Pulley so the Belt gets pulled down by the Variator as it climbs up Variator. So if you want your scoot to stay in the lower part of the Variator longer you put in a Stronger Contra Spring.

Stronger Clutch Springs Require Higher Rpms to get the Pads to come out and grab the Bell to Turn Your wheel.

Stronger Clutch Springs Also means that you have to keep the RPMS up to keep the Clutch from Disengaging. Cruising around town at 25-30 your rpms will be high at those speeds you always have to keep on the throttle otherwise the Pads will disengage from the bell.

I personally would rather have the Weakest Clutch Springs that get thrown out sooner so that the Pads are grabbing the bell say around 2500-3000 rpms. And control the RPMS with just the Contra Spring and Weights.

The way a CVT should be setup is when climbing a hill say at 6000 rpms, THE RPMS should STAY at 6000 going up the hill ONLY your speed goes down. Once you get it to that point you cannot get it any better, unless of course you add more Ponies to the motor.

This is what the different rated springs will do:

Example:

If your scoot CURRENTLY STARTS TO MOVE at 2500 rpms

1000 rated springs = Scoot will start to move around 3500 rpms.

1500 rated springs = Scoot will start to move around 4000 rpms.

2000 rated springs = Scoot will start to move around 4500 rpms.

Just add the spring ratings to your current RPMS that the scoot starts to move.

Now also remember the Clutch pads will Disengage at a much higher rpm as well.

Say you have the 2000 rated springs which require your rpms to be around 4500 for the Clutch pads to engage the bell. So you’re making a turn and you slow down and your rpms drop down say 3500 making the turn. Because the pads disengaged making the turn due to the lower rpms you will have a lag when you hit the throttle to come out of the turn until your rpms again get up to around 4500.

Just so you know what you will experience with changing to different springs either the Contra Spring or Clutch Springs.

TALLER GEARS IN THE TRANNY:

Changing the gears behind the Clutch to taller gears for more top end speed:

If you Change the Small Shaft that the Clutch turns by 1 more Tooth AND the Big Gear that the Small Shaft Turns by 1 Less Tooth that Drives the Output Shaft that turns the Wheel or (Sprocket with a Chain) you will gain about 3-4 mph more. For every number of teeth changed you can expect about 3-4mph more Top End Speed.

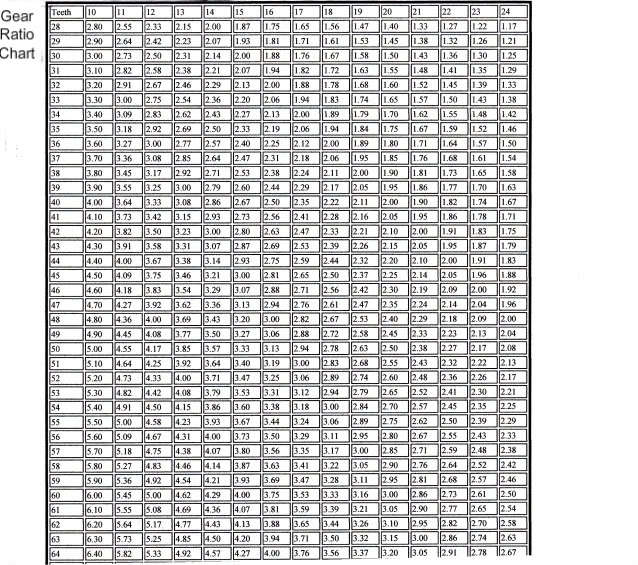

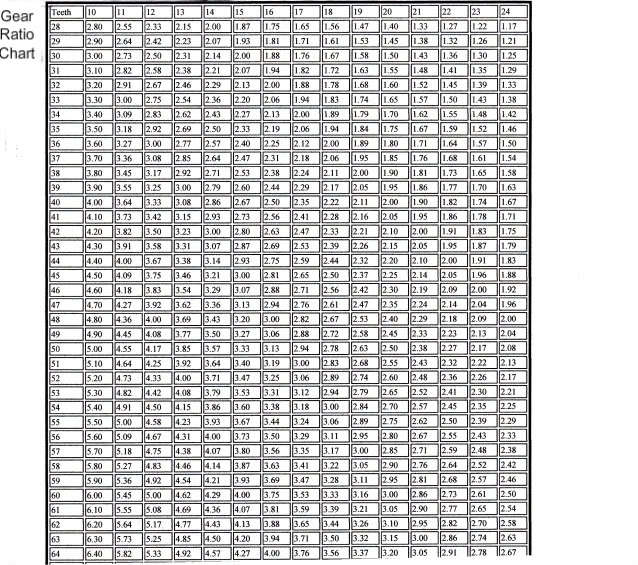

Here is a Gear Ratio Chart:

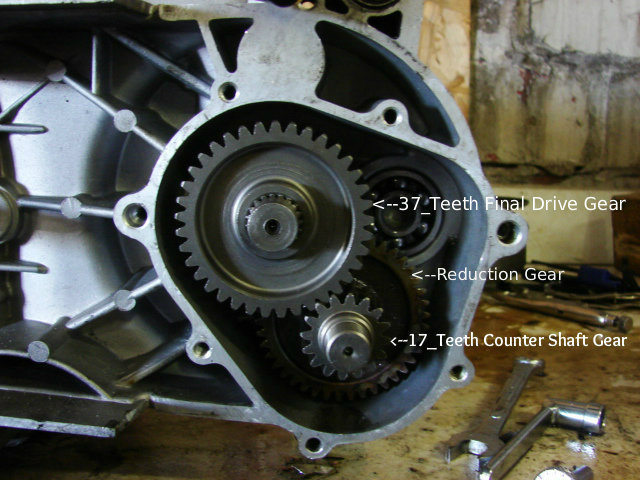

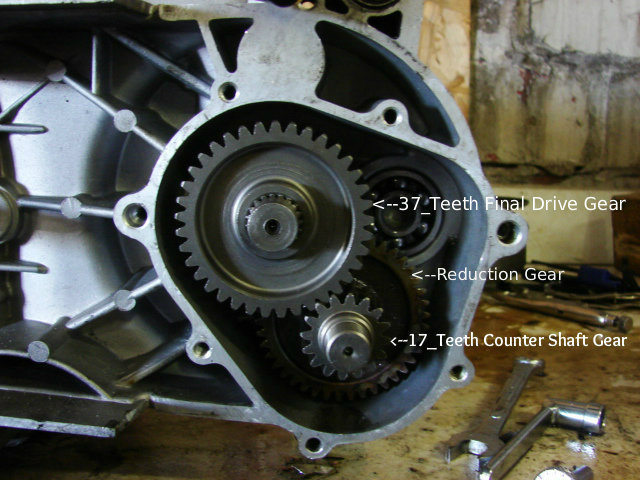

GEARS TO BE CHANGED:

The COUNTER SHAFT is what needs to be changed along with the FINAL DRIVE GEAR. The Reduction Gear on your current Shaft has to be PRESSED OFF and PRESSED ONTO the NEW COUNTER SHAFT that has more teeth to Drive the FINAL DRIVER GEAR that actually turns your wheel.

And as I have said many times A BIGGER GEAR WILL TURN A SMALLER GEAR FASTER. And that is what you are doing Getting a COUNTER SHAFT with MORE TEETH and getting a FINAL DRIVE GEAR with LESS TEETH. Just think of your CVT, The Front Variator the higher the belt climbs(more teeth..bigger circle) pulls the Clutch Pulleys apart to DROP the belt down(less teeth..smaller circle) for more top end.

Alleyoop

A lot of the Performance Variators they sell actually will not get you more top end speed. What most do is keep the weights lower in the ramps for good takeoff speeds and mid-range.

How a Variator will perform depends on how they built it and for what purpose. They do this by changing the angle of the ramps, length of the ramps and the curvature of the face plate where the belt rides on. A steeper ramp will keep the weights in the lower part of the ramp much longer which will give you strong takeoffs and good mid-range speeds. It requires more rpms but your scoot will get from Point A To Point B much quicker. A less angled ramp will go through the gearing ratio very smooth all the way to your top end speed.

Some Variators the ramps are to steep and short that the weights will not move out far enough in the ramps to push the belt as near as possible to the edge of the Variator and you will loose top end speed. This type of variator causes the acceleration not to be a nice smooth progression in speed. Since the ramps are shorter once you get to a certain speed say 45mph to get to 50mph is a slow process.

Some Variators the curvature of the face plate near the edge is to wide and your belt will never be able to get near the edge because the curvature near the edge of the variator is to great to hold the belt there.

So the best Variator must have ramps that are NOT to steep and a good Length along with a Face Plate that the Curvature is not too great so that the belt will move as close as possible to the edge and hold there.

The only ones that really give you more top end which also requires the right weights and rpms are the ones that are Bigger In Diameter than what you currently have on. Also good ramp length and the curvature of the face plate not to pronounced to allow the belt to actually get near the edge and hold. .

Here is what the Bigger Diameter will do. A bigger wheel turning a smaller wheel will turn the smaller wheel faster. So a bigger Variator the belt will climb out further thereby turning the Clutch pulley faster per revolution of the Variator.

And May I add to turn the Variator faster you need more RPMS. So its a combo of things to get the most speed. You can put in the heaviest weights and the belt will get squeezed to the edge of the Variator BUT if the RPMS are low you can actually go slower. So the RPMS have to be enough to keep turning the Variator faster once the belt reaches its highest point. That is why if you notice once you get rolling and the belt is already at its max height, as your RPMS start to climb you are picking up speed. In addition you can actually run out of gearing, what that means is no matter how many rpms your cranking out or the belt climbing to the edge, once you reach the limit of the gearing you will NOT get any more speed.

Here is also a comparsion of a OEM Variator and a PERFORMANCE Variator:

Another thing you can do is cut down the BOSS so that it squeezes the belt more between the pulleys without having to have really heavy weights to move the Variator out as far as possible. This will also give you the option to put in a belt that is NOT as wide as the Original so that it may drop further in the CLUCTH pulley to create a smaller wheel. Remember BIGGER WHEEL WILL TURN a SMALLER WHEEL MORE TIMES per 1 rotation of a bigger wheel.

CVT WEIGHTS:

The engines have pretty good torque have descent power as long as you do not go overboard.

Check your Variator first and see if Both Pulleys are the Same Size.

If the Variator itself is smaller than the Outside Pulley you can get what they call a PERFORMANCE Variator that is the same size as the Outside Pulley.

Belts will only climb as high as the Smallest Pulley.

So by having Equal Size Pulleys the belt now can be made to climb higher for more TOP END SPEED.

Also weights play a major roll on making the Belt climb higher.

Heavier weights Require Less RPMs to push the Belt up the Variator.

Lighter weights Require Higher RPMS to push the Belt up the Variator.

Roller Weights - Will Change your RPMS by 500-600 for every gram up or down.

Slider Weights - Will Change your RPMS by 200-350 for every gram up or down.

What I did is experiment with different Gram Rollers first they are cheap.

When I found the weights that I liked and at the RPMS I liked I then put in Dr. Pulley Sliders and went ONE gram Heavier on the Sliders So my Rpms would be almost the same as with the Gram Rollers I liked. So I gained just a little more top end with the Sliders due to Fact they are 1 Gram heavier than the Rollers and still the same RPMS.

Heavier weights will push the Variator out and squeeze the Belt more so it climbs higher for more top end. BUT to heavy of weights will make your takeoff and Mid-range sluggish.

Also Heavier weights will cause your RPMS to drop so you also have to watch out for that.

You want to run at or Near the RPMS the engine makes its MAX Horsepower. If it revs much higher than that the engine is Not producing any more horsepower and in many causes will loose horsepower due to floating valves etc.

Lighter weights take MORE RPMS to throw out the weights to Push Variator out to push the belt up the Variator. To Light and it will not push the belt as high as possible and you will loose top end but you will have a quicker takeoff and Mid-Range because the belt is staying in the lower gearing of the Variator longer.

CONTRA and CLUTCH PAD SPRINGS:

Stronger Contra Springs effects the RPMS required to OPEN THE CLUTCH PULLEY. The Stronger the Contra Spring the HIGHER RPMS is required to open the Clutch Pulley so the Belt gets pulled down by the Variator as it climbs up Variator. So if you want your scoot to stay in the lower part of the Variator longer you put in a Stronger Contra Spring.

Stronger Clutch Springs Require Higher Rpms to get the Pads to come out and grab the Bell to Turn Your wheel.

Stronger Clutch Springs Also means that you have to keep the RPMS up to keep the Clutch from Disengaging. Cruising around town at 25-30 your rpms will be high at those speeds you always have to keep on the throttle otherwise the Pads will disengage from the bell.

I personally would rather have the Weakest Clutch Springs that get thrown out sooner so that the Pads are grabbing the bell say around 2500-3000 rpms. And control the RPMS with just the Contra Spring and Weights.

The way a CVT should be setup is when climbing a hill say at 6000 rpms, THE RPMS should STAY at 6000 going up the hill ONLY your speed goes down. Once you get it to that point you cannot get it any better, unless of course you add more Ponies to the motor.

This is what the different rated springs will do:

Example:

If your scoot CURRENTLY STARTS TO MOVE at 2500 rpms

1000 rated springs = Scoot will start to move around 3500 rpms.

1500 rated springs = Scoot will start to move around 4000 rpms.

2000 rated springs = Scoot will start to move around 4500 rpms.

Just add the spring ratings to your current RPMS that the scoot starts to move.

Now also remember the Clutch pads will Disengage at a much higher rpm as well.

Say you have the 2000 rated springs which require your rpms to be around 4500 for the Clutch pads to engage the bell. So you’re making a turn and you slow down and your rpms drop down say 3500 making the turn. Because the pads disengaged making the turn due to the lower rpms you will have a lag when you hit the throttle to come out of the turn until your rpms again get up to around 4500.

Just so you know what you will experience with changing to different springs either the Contra Spring or Clutch Springs.

TALLER GEARS IN THE TRANNY:

Changing the gears behind the Clutch to taller gears for more top end speed:

If you Change the Small Shaft that the Clutch turns by 1 more Tooth AND the Big Gear that the Small Shaft Turns by 1 Less Tooth that Drives the Output Shaft that turns the Wheel or (Sprocket with a Chain) you will gain about 3-4 mph more. For every number of teeth changed you can expect about 3-4mph more Top End Speed.

Here is a Gear Ratio Chart:

GEARS TO BE CHANGED:

The COUNTER SHAFT is what needs to be changed along with the FINAL DRIVE GEAR. The Reduction Gear on your current Shaft has to be PRESSED OFF and PRESSED ONTO the NEW COUNTER SHAFT that has more teeth to Drive the FINAL DRIVER GEAR that actually turns your wheel.

And as I have said many times A BIGGER GEAR WILL TURN A SMALLER GEAR FASTER. And that is what you are doing Getting a COUNTER SHAFT with MORE TEETH and getting a FINAL DRIVE GEAR with LESS TEETH. Just think of your CVT, The Front Variator the higher the belt climbs(more teeth..bigger circle) pulls the Clutch Pulleys apart to DROP the belt down(less teeth..smaller circle) for more top end.

Alleyoop

..BAD TO THE BONE..

..BAD TO THE BONE..