Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on May 16, 2015 14:36:49 GMT -6

I went out and raised the needle/lowered the clip one notch (it was in the middle when I took the video I posted before):  The engine ran quite a bit worse. The hesitation on acceleration became much more pronounced and lasted longer. I adjusted the fuel mixture screw until I got the highest idle and here is the result. Since the engine behaved worse when I raised the needle/lowered the clip one notch, I decided to try to lower the needle/raise the clip one notch so the clip would be one notch above the middle. Again, I adjusted the mixture screw until I got the highest idle, which was a bit more difficult this time. The hesitation got a little better, but now I am having trouble at idle. Before (with the engine tuned as it was when I posted the first video) I could sit at a stoplight for about 20 seconds with the engine idling and take off without the engine dieing or almost dieing. Now, if I let the engine idle for anymore than 10 seconds, when I go to accelerate it slows down, hesitates, and dies or very nearly dies. I can keep the engine from dieing while sitting at a light if I lightly rev the engine just to the point where the clutch starts to engage, let off the throttle, and repeat until the light is green. Here and here are two videos showing what I mean. |

|

|

|

Post by Alleyoop on May 16, 2015 15:11:32 GMT -6

Ok your adjusting the fuel mixture after you set the needle which you should not have to do.

Setting the needle effects the mid-range either feeds it more fuel if you raise the needle(move the clip down) or less less fuel if you lower the needle(move the clip up).

So lets start back from scratch, put the clip in the center and adjust the fuel mixture to get the highest idle then Give the Throttle a quick twist and let go Get a Video of that so I can hear how the rpms act going up and coming down. If it bogs(hollow sound) that means it is getting to much air.

|

|

|

|

Post by cyborg on May 16, 2015 19:49:27 GMT -6

I think there's an air leak somewhere,,,, check the diaphragm glavy

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on May 16, 2015 20:30:48 GMT -6

Ok, I'll try and do that tomorrow, assuming I can get outside and work on the scoot when it isn't raining; the forecast for tomorrow for my area is 60% rain and 82 degrees and the day after that isn't much better. Time to put the air conditioner in!

Now when you say give the throttle a quick twist, do you mean blipping the throttle as if I were trying to rev-match while downshifting on a motorcycle, or do you mean do what I was doing in the previous videos; open the throttle and hold it open until the hesitation stops? If you mean the former, I can tell you now that the engine will probably bog down and possible die.

I did check the diaphragm today when I took the top cover off of the carb. It looked in very good condition, but I will look again and try something like shining a flashlight through it to see if there are any tears or pinholes I missed. I do have a spare diaphragm I can try out as well. I should note that I had the same problem with that diaphragm as I am having with the one I am using now, albeit with a different carburetor.

|

|

|

|

Post by Alleyoop on May 16, 2015 20:45:01 GMT -6

Start it up and let it warm up and adjust the fuel ratio to get the highest idle.

THEN:

Blip the throttle Grab it and give a quick twist and let go. If it bogs then we know it is sucking in to much air and not enough fuel. So you can always try taping off part of the air filter you have on to cut some air off. These 50s like the air box for some reason and many have trouble when a free flow filter is stuck on them. So if it bogs then get your tape ready and start from the end of the filter and wrap a tape all the way around and give it another blip if still bogs add another piece of tape to the one on there all the way around until it does not bog.

|

|

|

|

Post by cyborg on May 16, 2015 21:47:38 GMT -6

I just threw that out there,,,Alley has the answer,,,too much air

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on May 17, 2015 6:58:00 GMT -6

I will try that today. Hopefully the near 100% humidity won't throw off the results too much. Should I be adjusting the mixture screw each time after I put on a piece of tape or just do it once at the beginning and leave it?

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on May 17, 2015 16:26:34 GMT -6

Fix one problem, create another. I thought I'd start out by doing a thorough carburetor cleaning before taping up the air filter so I could rule out the possibility of some small passage in the carburetor being clogged. Now, I do mean actually cleaning the carburetor, not just spraying carb cleaner down the throat and calling it good. I completely disassembled the carburetor except for bracket that holds the throttle cable and the air valve that lies behind it.

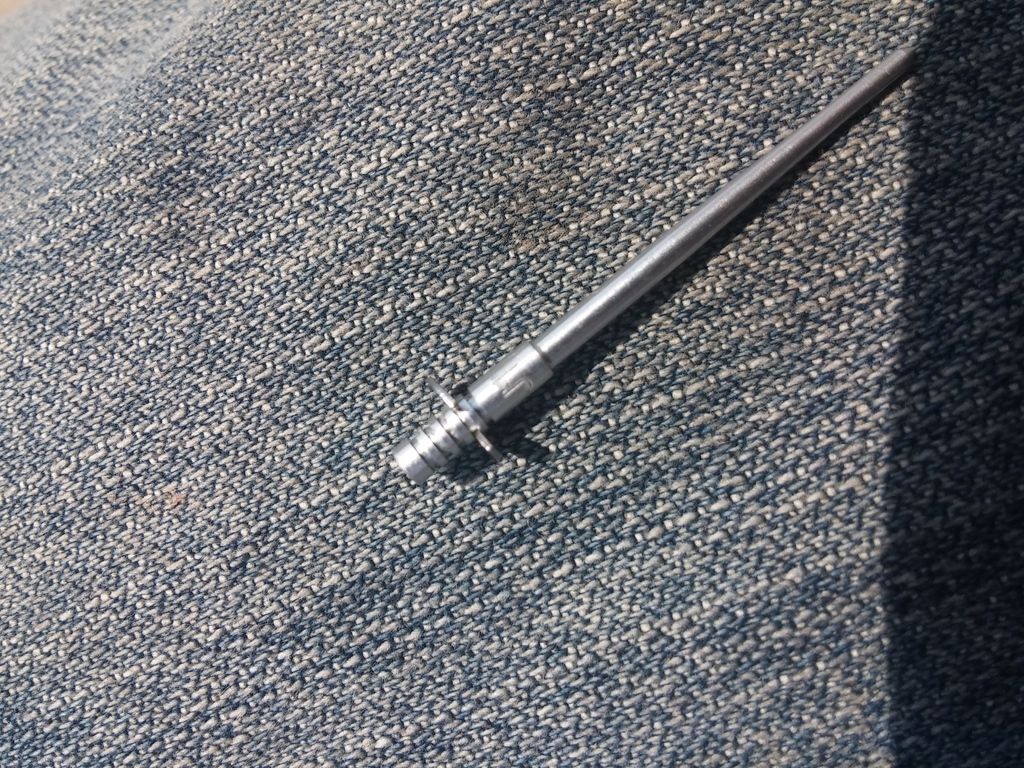

I cleaned every non-rubber/plastic part with carb cleaner, sprayed cleaner through every passage in the carb, and soaked the gasket in armor-all. I also moved the clip back to the center position. I checked the bowl floats and they didn't have any holes in them and there wasn't any fluid inside of them. The diaphragm looked completely intact:

It seems I was mistaken about which idle jet I was using. Apparently I've been using a #34:

I reassembled everything with no extra parts left over and put it back on the scoot. I started it up and immediately I noticed that the idle was much lower than it was before. I had to turn the idle screw in all the way and the engine still just barely kept running. I waited until the engine was up to operating temperature and the enricher was hot-to-the-touch and adjusted the mixture screw as best as I could to give me the highest idle. I turned the screw out to 4 1/2 turns and the engine still was just barely running with the idle screw all the way in. I gave the engine a quick, sharp blip on the throttle, the kind that would have caused it to bog and possible die before. This time it revved up with no hesitation and slowly returned to the idle speed. That told me that the carb was now running lean at/near idle. Here's a video showing the idle speed and a few throttle blips. By now, I had been working on the scoot for about 4 hours and I still had other things I needed to get done, so I called it a day. Part of me thinks I may have inadvertently clogged a passage in the carb or clogged the idle jet when I was trying to clean it. |

|

|

|

Post by Alleyoop on May 17, 2015 16:53:23 GMT -6

Good Video that helps a lot, Notice how the rpms do NOT DROP QUICKLY the rpms sort of hangs then drops that is a LITTLE LEAN CONDITION that causes that. And your correct it is a little lean, your really close now, SO DO not over do something.

Alleyoop

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on May 18, 2015 17:22:59 GMT -6

Having a garage in hot, humid weather is a double edged sword. One one hand, if the garage door and all windows are kept closed, the inside of the garage stays about 5-15 degrees cooler than the outside air. But, once you open the garage door, all the humidity condenses on the already slippery slick floor and you get this:  It doesn't look that bad in the picture, but there is a coating of moisture all along the floor of the garage where the humid air condenses onto the comparatively cold concrete floor. It gets worse the more you walk along the floor as well. I went out today and wanted to start by trying the engine with the same jets/tune/everything as yesterday when I stopped working on it so I could see if it ran the same or if there was something like a bubble in a fuel line or in one of the carb passages that could have worked it self out overnight. I went to start the engine the same as I always do, but it just wouldn't start. I always twist the throttle 2-3 times before trying to start the engine; using the accelerator pump as a primer. I suspected the pump wasn't working right because when I manually pushed the pump's plunger down my hand, it didn't feel the same as it usually does. I took the air filter off and looked at the point the fuel is supposed to come out of the pump when you twist the throttle; nothing came out. Now, yesterday during the carb cleaning, I did take the jet, spring, and ball out of the accelerator pump casting part to clean it. It appears that when I re-assembled those pieces, the ball (that acts as a one way valve) had too much pressure on it from the spring, causing it not to work right. I dis- and re-assembled those pieces, put the carb back together and put it back on the scoot. Before I tried starting the engine, I left the air filter off and twisted the throttle a few times; the accel. pump was working perfectly again. The engine ran just like it did yesterday before I called it a day, so my hope that the problem was just a fluke was gone. I took the carb off yet again and inspected the idle jet. I mentioned in my last post the I had the feeling that i may have clogged it while trying to clean out the carb. I looked through it and could see a very small size-of-a-human-hair piece of something in the jet. I again cleaned it out with carb cleaner as best as I could and re-inspected it. This time I could see straight through it; no obstructions. I re-installed it in the carb and put the carb back on the scoot. This time the engine ran just as it had been running during the first video I posted in this thread; it idled fine, but had the hesitation on acceleration. I took the scoot for a ride to fill up the gas tank and get the engine warmed up. When I came back, I tuned it with the mixture screw to get the highest idle, which turned out to be about 2 turns out. Here's a video of the engine running at that moment. Next I did as alley suggested and start taping up the air filter bit by bit, reducing the air going into the engine. I started on the end of the filter furthest away from the carb, taping up the end and about 1 inch of the sides. The engine ran exactly as it did in the video I linked to in the previous paragraph. I took a video of it running; blipping the throttle and holding the throttle until the engine stopped hesitating, but no matter what I do, photobucket will not let me upload it. Note that in all following videos with tape on the air filter, the tape was the only thing that changed. The mixture screw and idle screw were not touched. I noticed something about this time; when I open the throttle and keep it open until the engine stops hesitating, for about 3-5 seconds after that if I blip the throttle very quickly, not waiting for the hesitation to stop, the engine won't hesitate or bog down, it just revs up and slowly settles down. The longer I wait after revving the engine to blip the throttle, the more it hesitates and bogs. If I open the the throttle, wait for the hesitation to end, let the engine settle back down to idle, wait about 20 seconds, and quickly blip the throttle open and closed, the engine will bog down and die or nearly die. Something similar happens if I wait about 20 seconds or more and then hold the throttle open until the hesitation stops; The engine will heavily bog and hesitate and black smoke will come out of the exhaust until the hesitation stops. I captured this happening on a few videos I'll link to below. Since there was little-to-no difference with the first bit of the air filter taped off, I added another wrap of tape around the circumference of the filter and started the engine back up. Again there was almost no difference in the hesitation of the engine. Here is a video showing what I described above with holding the throttle open and quick blips.

I added another wrap of tape and repeated the process. This time I could notice that the hesitation was getting worse; lasting longer and bringing the engine closer to dieing. The first throttle opening in that video was after the engine had been idling for about 45 seconds. As you can hear, the hesitation and bogging was getting worse.

Again, I added another wrap of tape, this time there was only about a quarter-inch left for air to get in. As I thought might happen, the hesitation got even worse. The first throttle opening in that video was after the engine was idling for about 45 seconds.

By now I had been revving the scoot's engine for about 5 hours and I'm pretty sure my neighbors would like some quiet, so I stopped there for today.

I'm now starting to think that I might need to go the other way with fuel at and around idle - more lean. When there was that piece of debris obstructing the idle jet, the engine revved quickly without hesitation. When I removed the piece of debris, the engine hesitated and bogged once again. When I reduced the air going into the engine, making it run richer, the problem got worse. Tomorrow I think I'll try going down one size in idle jet to a #33. I sure do have enough different sizes to test them all:

|

|

|

|

Post by Alleyoop on May 18, 2015 17:44:17 GMT -6

Ok definitley getting to much fuel now, so the taping made it worse. So the only thing now is to try a smaller pilot jet.

Alleyoop

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on May 19, 2015 16:47:28 GMT -6

Am I missing something or doing something wrong here?

I swapped the 34 idle jet for a 33 idle jet and set about tuning the engine for highest idle after reaching operating temperature. The results were nearly identical as the ones I had with the 34 idle jet.

Photobucket doesn't seem to like any videos I shoot with my cell phone anymore so I uploaded them to youtube. Here is the engine with the 33 idle jet at operating temperature with the mixture screw 2 3/4 turns out:

The engine still stumbles when given a quick blip of the throttle after idling for longer than 5-10 seconds.

Next I put a 32 idle jet in and repeated the tuning process. Here are the results:

Not much difference form the 34 or the 33, perhaps just a little bit less hesitation. I still had a 30 idle jet I could go down to, so I did.

I actually have two 30 idle jets; one that came with the stock carburetor on the scoot and one that I bought from partsforscooters, along with all of the other idle jets except for the 35. The one that came in the carb seemed have either an ever-so-slightly smaller hole or a more roughly cut hole. The other one had a cleaner hole in it and what appeared to my eyes to be a slightly larger hole, so I tried that one next.

This time, the engine idled very poorly, but not as badly as it did in the video I took after attempting to clean out the carb. The idle speed oscillated and would never settle down at any one speed. If you let the engine idle for any length of time, just barely cracking open the throttle would make the engine bog, hesitate, and stutter. The hesitation from holding the throttle open was as bad as it had ever been, but now the engine very slowly ran down to idle after closing the throttle, indicating it was running lean. Here's a video showing the 30 idle jet:

It seems even with an incredibly lean idle jet, I still get hesitation on acceleration. I can't seem to replicate the response I had after I attempted to clean the carb. I can get a good idle with 32, 33, and 34 idle jets; but I can't eliminate that darn hesitation.

Perhaps I should try moving the needle while having the 33 and 32 idle jets installed?

|

|

|

|

Post by Alleyoop on May 19, 2015 17:44:55 GMT -6

WOW!! and I have to tell you it all has to do with that filter that is on there. Many have a crap load of trouble when they put on a Uni type filters. Some wind up putting on the air box to get them to run right. Most have added a tubing then put the Free flow filter, maybe having the filter right on the carb is just to much. BUT yes slap in the better idling and running jets that you have and then work on the needle, see if that helps the situation. Here is another one that had troubles notice I had him cover part of the Free Flow on his as well.  |

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on May 19, 2015 19:09:42 GMT -6

If I could put the stock air filter back on, I absolutely would. Unfortunately, the radiator and hoses for my oil cooler are in the way.  In fact they are what caused me to remove the stock airbox in the first place; there was no other way to route the hoses and position the radiator. I even designed and made my own airbox for the pod-style filter, but due to one small oversight (I took all of the measurements for its fitment with the scoot on the c-stand, forgetting that the engine with the carb on it moves a bit when taken off the c-stand) it didn't work. I still have the stock airbox, so I could try to either make it fit in some other place or make a pipe to put between the carb and the pod filter. Either way, tomorrow I will start with the 33 idle jet and try different needle positions. If no combination of idle jets and needle positions work, I'll move onto the air filter. If that doesn't work, then, unless I thought of something else by then... I'll just live with the hesitation. |

|

|

|

Post by Alleyoop on May 19, 2015 19:25:46 GMT -6

Glavey, You put on a OIL COOLER "VERY COOL"!! Take picture of your setup and do a little write up and I will post it in the TECH SECTION for you. That would help others wanting to slap on a oil cooler.

Alleyoop

|

|