Senior Clinician

Currently Offline

This trike you fly!

Posts: 166  Likes: 0

Likes: 0

Joined: Jul 29, 2012 10:18:39 GMT -6

|

Post by new2scootn on Sept 12, 2013 23:26:58 GMT -6

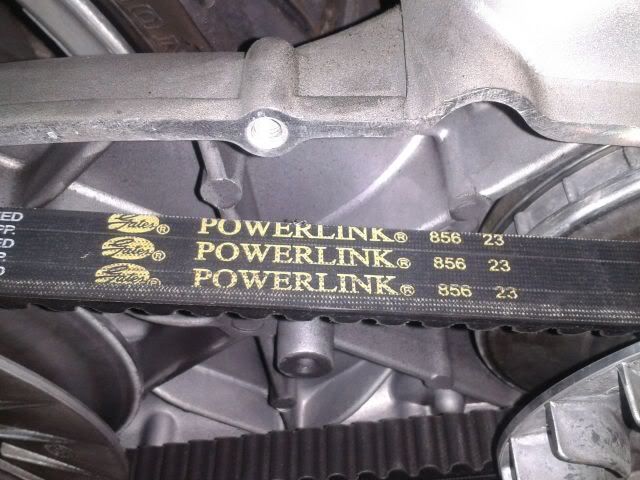

I swear, I'm gonna make this thing rideable(and reliable?) if it kills me! Ripped the motor mount out again(with the intention of replacing the crappy Chinese rubber bushings with either urethane bushings or bearings), and figured since she's half apart anyway I might as well tear into that transmission and see what size belt she has and why my clutch is engaging even at low idle. Was happy to see the belt in good condition(hell, it should be-only got 800 miles on her! But the clutch has been fighting the belt recently) and shocked to see that it was a Gates Powerlink belt! Then I read that there are knock-off Gates belts... but who knows? Hopefully this is the real deal--it looks and feels like a high quality belt. Here's some pics.   And for any Sunny Roadrunner 300 RT owners out there there's your belt size: 856-23(856 mm long by 23 mm wide). I also found out that the belt teeth are at a 30 degree angle so this belt is a 856-23-30. I took a couple of shots of the clutch too before I tear it apart...   And here's a couple shots of my rear tire. Almost completely bald in the center tread! 800 miles! Did I already mention that Chinese rubber sucks?...   Well, tomorrow I'll tear into that clutch and see what it's problem is. ;D  |

|

Senior Clinician

Currently Offline

This trike you fly!

Posts: 166  Likes: 0

Likes: 0

Joined: Jul 29, 2012 10:18:39 GMT -6

|

Post by new2scootn on Sept 15, 2013 7:55:29 GMT -6

So I took the variator and clutch off.  Naturally I wasn't carefull to hold the variator together as I slid it off and the pulley's separated and all the rollers came out of their tracks...  (LOL!) Ah, but I wanted to take it apart anyway to check the rollers. So far I haven't found any problem with the clutch. Was expecting to find a broken or weak pad spring but all appear ok. I haven't been able to crack it completely open yet 'cause I haven't been able to find a 46mm or 1 and 13/16 socket.  Local auto parts stores top out at 1 and 3/4(a 16th too small!). I am thinking maybe a piece of brake pad got stuck somewhere and wasn't allowing one or more of the pad arms to retract. I say this because a couple of the pads had a bunch of extra pad material kinda squished out where they are bonded to the arm but I wasn't payin' attention when I first took the clutch bell off to see if any crap fell out. Arms don't seem to be binding either but once I get the thing apart I will know for sure. If you read this Alley, do you think that since I'm in there already I should just replace the clutch arm springs? I plan to replace the Contra spring with a stiffer one just to experiment(I know the possible downside) so I wouldn't want to go with stiffer arm spings. Everything worked great at first until approx 600 to 700 miles, then clutch started grabbing(rear wheel would spin and had a lot of resistance when on center stand no matter how low I brought the idle down). I'll post a picture once I take one of the clutch arm pads--it looks to me like one of the three is worn down lower but the tension of that arm spring feels the same as the others and it doesn't seem to be binding...  |

|

|

|

Post by kz1000st on Sept 15, 2013 9:28:13 GMT -6

I know it's kind of late for this but I never dig into something when it's working. Weak clutch springs are usually evidenced by high RPM engagement. If I was worried about low RPM engagement, and I wouldn't, because of crud in the clutch I would have sprayed the clutch real good with brake parts cleaner, watched the crud pour out and let it dry.

All machines change as they wear in. Clutch engagements change, engine sounds change, power characteristics change. As long as it's not stalling or slipping when the clutch engages, it's fine. Lower speed engagement just means the pads have bedded in and are biting sooner.

|

|

|

|

Post by Alleyoop on Sept 15, 2013 10:09:53 GMT -6

It is the opposite of what KZ said that "Weak Clutch Springs are usually evidenced by high RPM Engagement". The weaker the Clutch springs the sooner they get thrown out to grab the bell, the more miles the springs get weaker NOT stronger.

As an example with OEM springs they are usually rated at 700-800. Your scoot may start to move at say 2500 rpms. If you put in 1000 rated springs now your scoot will start to move when the RPMS are about 3500 rpms, 2000 rated springs 4500 rpms etc.. So now to get the clutch pads to grab the bell require a lot more rpms.

I personally do not like to cruise around say at 30-35 with high rpms keeping the Clutch pads engaged.

My Trike I have the weakest springs possible and it throws out the Clutch pads at around 2300 rpms. They also Disengage at around that same rpm. So coming to a stop sign or light It slow down quite a bit without having to us my brakes and doesn't freewheel till around 2300-2500.

Alleyoop

|

|

|

|

Post by kz1000st on Sept 15, 2013 11:11:46 GMT -6

Sorry, my mistake. You're right of course. Weak springs should engage sooner.

|

|

Senior Clinician

Currently Offline

This trike you fly!

Posts: 166  Likes: 0

Likes: 0

Joined: Jul 29, 2012 10:18:39 GMT -6

|

Post by new2scootn on Sept 17, 2013 0:36:40 GMT -6

Ok, I found the problem with my clutch. This is my first cvt so maybe they're all made like this but...  Each of the arms have one of these rubber bumpers that is binding and limiting its range of motion. Here's how the arms look against the bumper, then the next pic is of the same arm with the bumper removed. You can see how much tighter inward the arm(with the spring removed) comes without the bumper.   And that's the problem! The arms can't pull all the way in, and with them stickin' out they scrape against the drum and drive the rear wheel! So the real question is...Why now, after 800 miles of driving is this happening? And do I really need these stupid things(what is they're purpose)  |

|

|

|

Post by Alleyoop on Sept 17, 2013 11:43:38 GMT -6

It appears that ONE bumper is to high it should go into a little open area of the PAD ARM. Those are there to hold them when they disengage and not rattle around. If you look the other TWO ALSO have them, get a screwdriver and push open one of the others and you will see the rubber bumpers as well, but they slip into a opening on the pad arm.

But you found the problem and it appears IT IS ONLY THAT ONE. Maybe the pin is to high or could be made bad and in the wrong place on the arm.

Alleyoop

|

|

Senior Clinician

Currently Offline

This trike you fly!

Posts: 166  Likes: 0

Likes: 0

Joined: Jul 29, 2012 10:18:39 GMT -6

|

Post by new2scootn on Sept 17, 2013 19:43:59 GMT -6

Hey Alley, thanks for the input. No it's not only that one bumper, it's all three. They are all distorted and binding. I'm thinking of replacing them with some high temp o-rings. Oh, and of course I made more work for myself by overstretching that one spring I removed so now I have to replace them. I can't believe how hard it is to find replacement clutch springs for this thing! I don't want to order them from Sunny/Scooter Depot/whatever they're callin' themselves today, and almost all that I am finding are for 50cc to 150cc machines. Any suggestions for a source for clutch springs for a 300cc Yamaha clone engine?

|

|

|

|

Post by Alleyoop on Sept 17, 2013 19:53:20 GMT -6

On your first pic the other pads are down on the rubber bumpers if you look the ARMS have a slot that slam down around the rubber. They hold the arms from flopping around. All the clutchs have them even mine. But that one is hold THAT ONE PAD open so something is wrong with that one.

I will see if I can find the clutch springs for it.

Alleyoop

|

|