Clinician

Currently Offline

Posts: 38

Likes: 0

Joined: Jul 15, 2010 10:29:12 GMT -6

|

Post by tk3000 on Jul 1, 2011 20:08:12 GMT -6

Hello Folks,

I know my way around the gy6 4-stroke engine and 2-stroke engines, but I am not very familiar with the CN250. Valves seems to be properly adjusted, installed new carburetor just in case since I suspected that maybe it was a carburetor related issue (enriching circuit or cut-off valve) and cleaned all the passageways and galleries, renews all vacuum lines/fuel lines and clamps, coolant and cooling system seems in good shape, etc. When I first turn the engine on and try to open the throttle it starts to sputter and wants to die even I try open the it slightly, after about 15 minutes of the bike running (idling) it starts to get more responsive and seems to respond to throttle input more or less ok. But still it seems to be restricted somewhat since it does not want to go fast enough (I did not try in a long stretch though). I tested engine compression with a cold engine and obtained around 100 PSI which at first seems low. Also to add up to the problem there is an oil leaking underneath the engine (few drops of oil that manifest themselves mostly when the engine is running and is still warm).

One possibility that I am considering is that the the engine case is not properly sealed (I verified the torque in some bolts, and they seemed ok; but I am not sure if I check all of them) and thus it is leaking vacuum and also some oil, and once it gets warmer the metal would expand thus acquiring better sealing which would then help minimize the sputtering and stuttering that tend to happen during the first 10 minutes of engine running whenever I would open the throttle. Also the oil leakage gets worse whenever the engine is running or still hot, the oil leakage does not seem to originate from underneath the engine. Is there any spot on this engine were the oil leaking and any vacuum leaking would be more likely to originate from; or maybe there are another root for such sudden death of the engine whenever I try to open the throttle for the fist 10 minutes of running the engine? Any input would be appreaciated.

tk3000

|

|

|

|

Post by Cruiser on Jul 1, 2011 21:54:51 GMT -6

Hi tk3000. How many miles on your scoot? The compression specs for this engine is 213 pounds @ 600 rpm.

A leaking head gasket could cause both lower compression and an oil leak. Check the area around the head gasket closely.

This engine is prone to cracking of the intake manifold which can cause a lean condition. It sounds like the engine is starving which may be an intake manifold leak.

|

|

Clinician

Currently Offline

Posts: 38

Likes: 0

Joined: Jul 15, 2010 10:29:12 GMT -6

|

Post by tk3000 on Jul 1, 2011 23:55:49 GMT -6

Hi tk3000. How many miles on your scoot? The compression specs for this engine is 213 pounds @ 600 rpm. A leaking head gasket could cause both lower compression and an oil leak. Check the area around the head gasket closely. This engine is prone to cracking of the intake manifold which can cause a lean condition. It sounds like the engine is starving which may be an intake manifold leak. Thanks Cruiser! It has less than 40 miles, it is a storm 250cc I bought some time ago (about 9 months ago), but I haven't been around to work on it, so it was seating in my garage most of the time. It has two radiators, and the plumbing underneath was leaking so I also built some contraption out of copper pipes and fittings to replace the original plumbing underneath (that is made of out soft and brittle aluminum) as shown below:  Would you know about any contraindication about using copper pipes in such setup (with automotive coolant)? I will check the head gasket and the intake manifold next week. Hopefully, it is just the intake manifold! I will let you the findings. tk3000 |

|

|

|

Post by Cruiser on Jul 2, 2011 0:43:04 GMT -6

Using copper should be no problem. I have seen copper used by other people in their scoots with no adverse affects.

|

|

Clinician

Currently Offline

Posts: 38

Likes: 0

Joined: Jul 15, 2010 10:29:12 GMT -6

|

Post by tk3000 on Jul 16, 2011 5:05:49 GMT -6

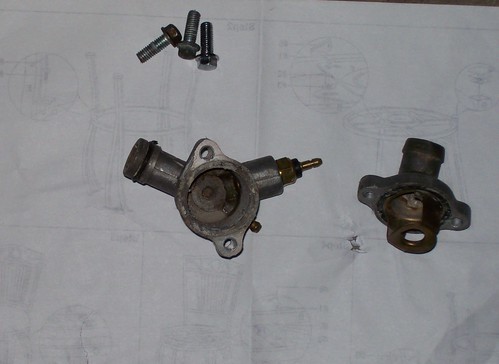

Using copper should be no problem. I have seen copper used by other people in their scoots with no adverse affects. I would assume the copper would ok too since it is used to carry all sorts of fluids and chemicals, also its specific heat is lower (copper's specific heat is lower than aluminum's specific heat). I happen to have two 250cc bikes both in my garage for some time, and I have been away for most of the time lately, so no many chances to work on them or ride them lately; but I hope to change that soon. I haven't looked at the one that has a vacuum leak yet (maybe cracked manifold or cylinder head gasket damaged) but I hope to check it out this weekend. Nonetheless I have been working on the cooling system of the other ones (woody black 250cc, storm as well): I fabricated an underneath plumbing contraption out of aluminum pipes and fitting as shown below:  Partial setup shown below, red high-temp permatex gasket maker was used to the water pump housing, inside of the pump and impeller were checked and cleaned and seemed to be ok.  After assemblage, cleaning and adjusting of carburetor and then refilling of the coolant fluid (50% coolant, 50% distilled water) the bike started right up, but it was overheating very fast and with lots of intensity. On occasion of refilling the coolant I burped the system of any pockets of air by leaving it idling for a while with the coolant pressure valve open and rocket the bike help in the process. But the main radiator was completely cool (lower radiator), the upper radiator got hot after a 5 minutes of engine running), the copper pipes underneath were pretty hot, and then engine case and specially the rubber body of the enricher on the carburetor were very hot very hot indeed. So clearly not coolant was circulating up to the lower radiator (the larger and main one) and maybe not even circulating at all to some part of the engine. So I decided to take a closer look at the thermostat; removed, opened it up, and took a look inside, as shown below:  I was expecting to find some spring loaded mechanism inside the thermostat housing that would open or shut the flow of coolant to the engine depending on the engine temperature (shutting the flow in order to allow the engine to reach operating temperature for instance), but found nothing. Is that the way it should be? Thanks, tk3000 |

|

|

|

Post by Cruiser on Jul 16, 2011 21:57:47 GMT -6

|

|

Clinician

Currently Offline

Posts: 38

Likes: 0

Joined: Jul 15, 2010 10:29:12 GMT -6

|

Post by tk3000 on Jul 16, 2011 23:21:23 GMT -6

It is crazy that the thermostat was simply absent or non-existant; that certainly explain at least part of the cooling issues. I will check the other one I have to make sure it has a thermostator inside the thermostator housing. tk |

|