|

|

Post by royldoc on Jul 7, 2013 19:56:01 GMT -6

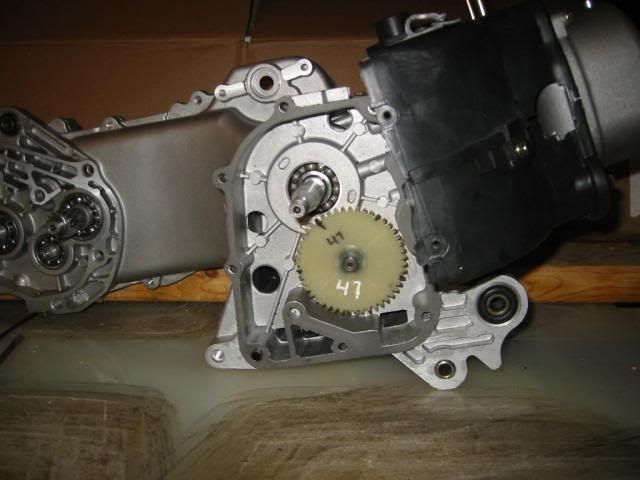

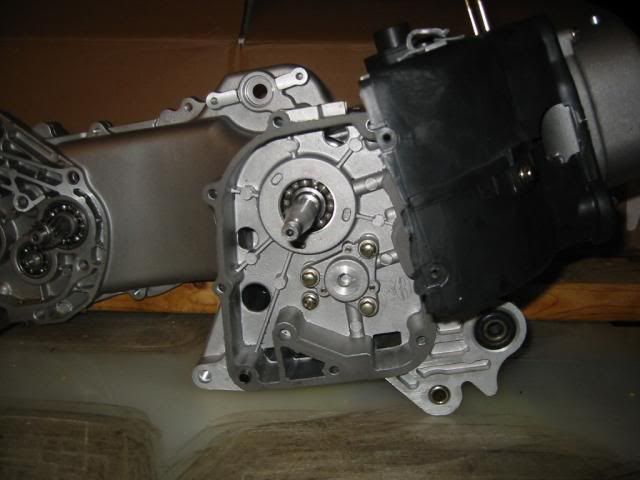

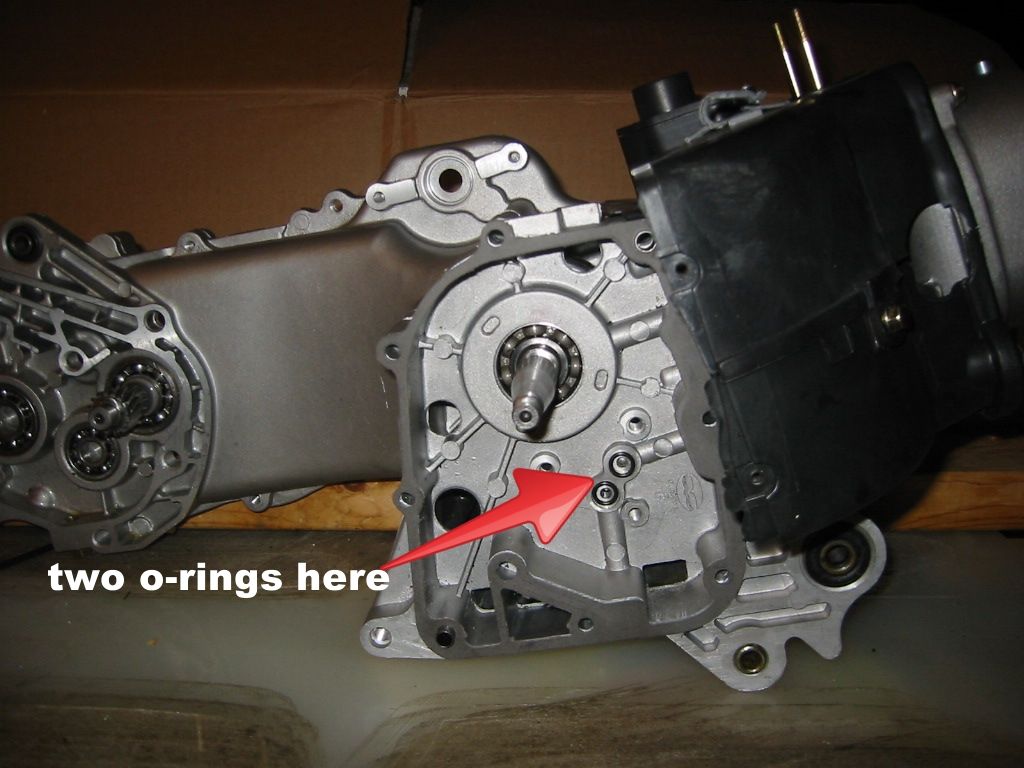

This is going to be a step by step of how to replace the oil pump on a qmb139 engine. Step 1: drain the oil and unplug stator harness Step 2: Remove the fan cover (it is not necessary to remove the complete shroud) Step 3: remove the fan Step 4: Remove the flywheel nut and use a flywheel puller to remove the flywheel.(be careful not to lose the small key in the crankshaft)  step 5: Remove the ignition trigger coil.(it is not necessary to remove the stator coils)  Step 6: remove the eight bolts holding the crankcase cove to the case.(keep track of which holes the bolts come out of as they are different lengths) You my need to tap the cover with a plastic/rubber mallet to free it up. (be careful to not lose the two locator dowel pins) Step 6: Remove the oil pump gear, remove the three oil pump bolts, remove the pump. (there is two o-rings behind the pump to seal the inlet and outlet ports)    Roy |

|

Doc's Anything Goes

Currently Offline

Posts: 2,739

Likes: 66

Joined: Oct 23, 2010 19:29:21 GMT -6

|

Post by tvnacman on Jul 7, 2013 20:00:51 GMT -6

Roy it is a pleasure to read your posts .

John

|

|

|

|

Post by royldoc on Jul 7, 2013 22:53:19 GMT -6

Thank You John.

Roy

|

|

|

|

Post by Bashan on Jul 9, 2013 5:18:58 GMT -6

Wow Roy, thanks for posting this. With your permission I'd like to eventually move it to the tech Library. Thanks again man, Rich

|

|

|

|

Post by royldoc on Jul 9, 2013 11:43:49 GMT -6

Sure Rich, you can move this if you want.

Roy

|

|

Senior Clinician

Currently Offline

Posts: 212

Likes: 2

Joined: Jun 1, 2011 16:30:33 GMT -6

|

Post by cdoublejj on Jul 14, 2013 0:42:40 GMT -6

is there such thing as a high volume oil pump for 139qmb if so do they really work?

|

|

|

|

Post by royldoc on Jul 14, 2013 3:40:16 GMT -6

is there such thing as a high volume oil pump for 139qmb if so do they really work? I'm not sure, but don't think so. I have only found two different oil pumps. one uses a 16 tooth drive gear on the crankshaft and a 33 tooth driven gear on the pump, it turns at a ratio of 2.0625:1. This pump has internal gears that are 8.75mm thick. The other pump uses a 22 tooth drive gear on the crankshaft and a 47 tooth driven gear on the pump, it turns at a ratio of 2.1362:1. This pump has internal gears that are 10mm thick. The internal gears of the pump are the same diameter and have the same number of teeth. I haven't tested the difference in flow of the two pumps, but I think it will be about the same. Even though the first pump turns a little faster the internal gears are thinner. The second pump turns a little slower, but the internal gears are thicker. The thinner gears will move less volume but turn faster than thicker gears. If the two pumps had the same size drive gears and driven gears and they turned the same rpm the pump with thicker gears would have a greater flow. |

|

Senior Clinician

Currently Offline

Posts: 212

Likes: 2

Joined: Jun 1, 2011 16:30:33 GMT -6

|

Post by cdoublejj on Jul 21, 2013 0:39:51 GMT -6

damn. Well i was thinking if there was one with higher volume it might help reliability and might be able to Handel those oil cooler kits you see being sold.

it's not possible to replace the thinner internal gears with thicker ones but, keep the smaller outer gear for more rpms is it?

|

|

|

|

Post by royldoc on Jul 21, 2013 1:27:40 GMT -6

I am thinking it may be possible to drill out the center of a 33 tooth gear and press the shaft from a 47 tooth gear in it. I need to order a spare 47 tooth gear though. If not I will have a shaft made at my local machine shop. This will allow me to use the pump with thicker gears turning at the faster ratio. I would prefer to use the shaft from a 47 tooth pump, because the end of the shaft is supported by the case cover. The shaft from a 33 tooth pump has a threaded end and the gear is held on by a nut, so it cant go into the hole in the case cover and is not supported.

Roy

|

|