Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Jul 10, 2014 11:55:33 GMT -6

I have an idea involving for a project involving the dipstick and some epoxy and I want to make sure the epoxy will adhere to it.

|

|

Ad Free Donut

Currently Offline

A bike is music to my ears.

Posts: 1,655

Likes: 93

Joined: Oct 22, 2013 4:11:04 GMT -6

|

Post by Guitarman on Jul 10, 2014 12:05:31 GMT -6

Ummm... Uhhh... Ah.. Nevermind.  |

|

|

|

Post by Alleyoop on Jul 10, 2014 12:07:33 GMT -6

YEP BAD IDEA, you better lay off that cheese  |

|

Ad Free Donut

Currently Offline

A bike is music to my ears.

Posts: 1,655

Likes: 93

Joined: Oct 22, 2013 4:11:04 GMT -6

|

Post by Guitarman on Jul 10, 2014 14:14:12 GMT -6

Sorry... Maybe if you tell us the idea you had...

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Jul 10, 2014 15:05:34 GMT -6

B...b...b... but I love cheese! I really do. Too much probably.

I want to make a secondary crank case vent by drilling a hole though the dipstick and gluing in a hose barb. Similar to the oil catch can scrappydog sells, but keeping the crosshatched portion of the stick connected.

|

|

|

|

Post by Bashan on Jul 10, 2014 15:46:02 GMT -6

I'm sure they make some sort of automotive epoxy that would hold. But this is what I would do. #1 drill a hole down through the dipstick that will fit the small diameter of a grommet from auto weinie. #2, dill a slightly larger hole each side of it and leave an appropriate distance between them to accommodate the barrel of the grommet.

#3, jam the grommet down into the opening so that it catches and seal on each side of the barrel. #4, slide a brass fitting or tube down in there nice and snug. Hook whatever line you want to it and zip tie it off to reduce stress on the fiting.

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Jul 10, 2014 16:36:35 GMT -6

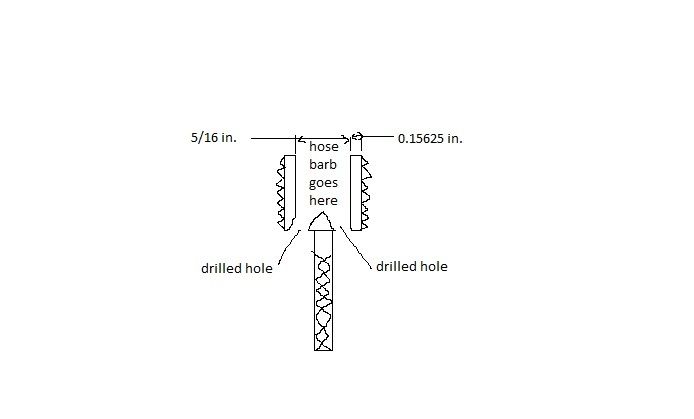

Nice illustration bash, I do like the idea, but I have a slightly different idea. I'll try to illustrate it as best I can. Behold my horrid microsoft paint skills:  Basically, I will drill two small holes upwards from the bottom between the threads and the crosshatched stick angled toward the center. Then I will drill straight down from the top of the stick to where the two small holes intersect. Put epoxy in top hole, jam hose barb in. Re-drill small holes if the barb or epoxy obstructed them. |

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Jul 11, 2014 15:49:36 GMT -6

Ok, it looks like my idea, and entire project will be no good. I took out the dipstick and shined a flashlight in to the hole and I saw that there isn't an air gap between the oil level and the engine casing; meaning if I were to do what I was planning on doing, the positive crank case pressure would push oil out of the dipstick hole until the oil level was low enough to allow air into the tube.

|

|

Ad Free Donut

Currently Offline

A bike is music to my ears.

Posts: 1,655

Likes: 93

Joined: Oct 22, 2013 4:11:04 GMT -6

|

Post by Guitarman on Jul 11, 2014 16:00:30 GMT -6

I was thinking that but I wasn't sure what you had in mind so I was biding my time...

|

|

|

|

Post by Bashan on Jul 11, 2014 22:39:17 GMT -6

How about drill and tap around the starter gear or maybe starter reduction gear? All kinds of air space up there with minimal oil throw.

|

|

Ad Free Donut

Currently Offline

A bike is music to my ears.

Posts: 1,655

Likes: 93

Joined: Oct 22, 2013 4:11:04 GMT -6

|

Post by Guitarman on Jul 11, 2014 23:10:14 GMT -6

So... WHY does one need a secondary crankcase vent?

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Jul 12, 2014 8:57:48 GMT -6

How about drill and tap around the starter gear or maybe starter reduction gear? All kinds of air space up there with minimal oil throw.

I think that is a 150cc; my starter and bendix look completely different. I would like a secondary crank case vent because I believe (I don't know this for a fact, but I do believe) the single vent at the valve cover is inadequate at efficiently releasing all of the pressurized air from the crank case, especially since I have a big bore kit installed. |

|

|

|

Post by Bashan on Jul 12, 2014 9:44:37 GMT -6

Yes it's a 150, I'm sorry, I do that all the time. It's egocentrism, I frame the world in terms of my world. If I have 150s then EVERYBODY has 150s.

I've often thought about the case vent through the valve cover. Considering how the piston is slamming up and down it would need a hell of a vent, or two vents, to release the pressure waves that build up. That is mainly on 150s where the piston is actually big enough to see with the naked eye and actually compresses enough air/fuel to generate more than a nanojoule of energy which is the benchmark for the 139QMB thingie some mopeds have.

I'M KIDDING! Don't start writing me people, I'm just goofing around. Now if you'll excuse me I have to go finish up adjusting the valves on my SYM 300 which has a HUGE piston along with EFI, ceramic cylinder liner, and all sorts of stuff. Yep, too numerous to list all the things...especially the diameter of the piston..just too huge.

|

|

|

|

Post by cyborg on Jul 12, 2014 10:29:02 GMT -6

Is this the very same 300 that you were contemplating suicide over?

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Jul 12, 2014 10:43:51 GMT -6

I have thought about drilling and tapping a hole for the second vent, but I am so damn scared of metal filings in the crankcase.

If I wanted to, I guess I could remove the engine from the scoot and crack the case open so I'll be able to get any filings/shavings, but that seems like a lot of work.

Maybe I could just drill/tap a second hole in the valve cover... although I get the feeling there is a lot of oil splashing around in there.

Bash, remember the theory (especially true for harley riders) that the size and loudness of the engine is inversely proportionate to the size of your... you know... dipstick.

|

|