Scooter Doc

Currently Offline

Posts: 294

Likes: 0

Joined: Dec 12, 2011 16:49:03 GMT -6

|

Post by tmec on Jan 25, 2012 14:13:02 GMT -6

I can take the floorboard off this one on the bench and take more detailed photos. You may need a donor scooter to hack stuff off the frame for this, i passed up a free frame yesterday.

What I tried to show in the photos is that on a QMB motor when load is applied yes the shock compresses but that rubber bumper also compresses against that crossmember. There is so much rubber on the way these are mounted because the engine is actually the rear suspension swingarm too and without all the rubber the mounting points on the case will break off..one big pothole and crack your motor is laying in the road...and so are you. I have seen guys who race use a solid bar in place of the shock/spring in the back for traction and some who have tried solid mounting for the motormount but this has led to broken cases on more than one occasion. Its very unsafe for any scooter.

The engine mount with bolts on the engine above is for sale. $40 free shipping.

|

|

Senior Clinician

Currently Offline

Posts: 130

Likes: 2

Joined: Dec 13, 2011 2:27:16 GMT -6

|

Post by new2scooters on Jan 26, 2012 0:15:39 GMT -6

Thanks to all who have taken time to reply. Your input is certainly appreciated and will save me not only a lot of design time but I'll end up with a better riding scoot when it is done.... Thanks again! Based on your input, I've started construction of the swing arm mount however I need to pick up some wider steel for mounting it to the frame.Will get that next time I get to town and with any luck I'll find it in the offcut bin where it is only $1 per lb.

Project update: rear shock mount and front pivot for swing arm fabbed and welded.

|

|

Senior Clinician

Currently Offline

Posts: 130

Likes: 2

Joined: Dec 13, 2011 2:27:16 GMT -6

|

Post by new2scooters on Jan 26, 2012 0:25:09 GMT -6

I can take the floorboard off this one on the bench and take more detailed photos. You may need a donor scooter to hack stuff off the frame for this, i passed up a free frame yesterday. Thanks for the input tmec. I have salvaged the swingarm from the engine donor scooter. It looks very similar to your photo. I did have concerns about mounting the engine in a fixed position which is why I posted the question and based on the response I got, it certainly will be avoided. Experience is always the best teacher, especially in this case.... Thanks again for your input. |

|

Doc's Anything Goes

Currently Offline

Say no to scooter abuse

Say no to scooter abuse

Posts: 3,873

Likes: 156

Joined: Mar 31, 2010 19:07:16 GMT -6

|

Post by jct842 on Jan 26, 2012 1:07:24 GMT -6

The nice thing about here is that some one else has most likely done it or been through it. Not sure if any of us are on boric acid though. john

|

|

Senior Clinician

Currently Offline

Posts: 130

Likes: 2

Joined: Dec 13, 2011 2:27:16 GMT -6

|

Post by new2scooters on Jan 26, 2012 9:34:22 GMT -6

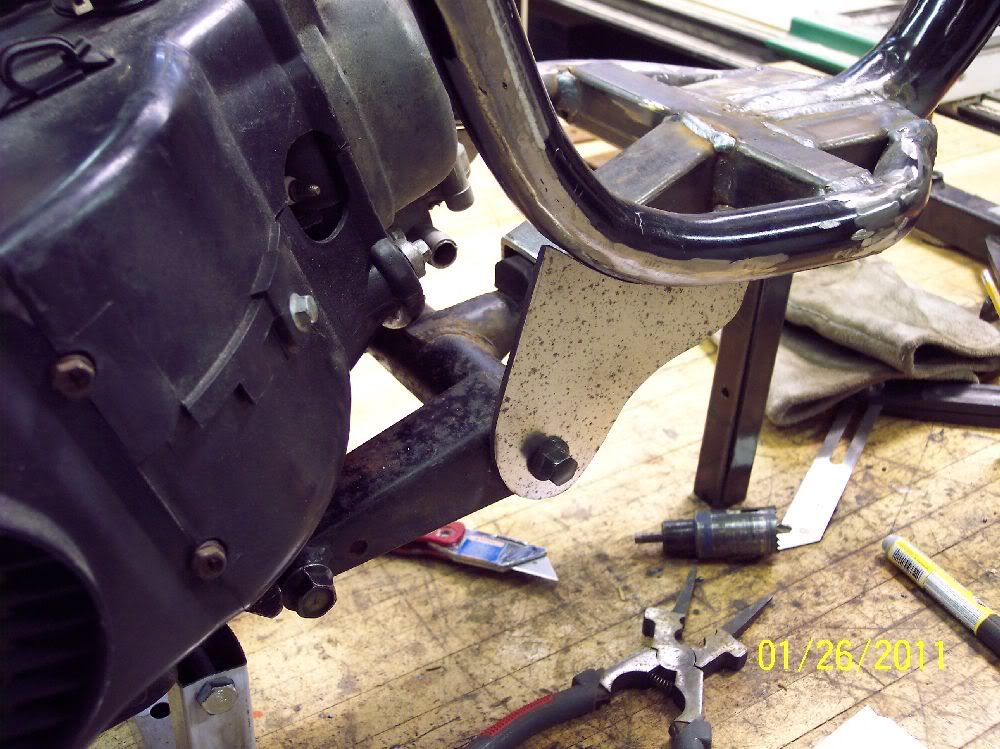

Photo update: Upper shock mount and start of swingarm fabrication:  |

|

Scooter Doc

Currently Offline

Posts: 294

Likes: 0

Joined: Dec 12, 2011 16:49:03 GMT -6

|

Post by tmec on Jan 26, 2012 18:13:52 GMT -6

lookin really really good!

|

|

Senior Clinician

Currently Offline

Posts: 130

Likes: 2

Joined: Dec 13, 2011 2:27:16 GMT -6

|

Post by new2scooters on Jan 27, 2012 0:19:19 GMT -6

Photo update: Swingarm brackets are done. Ready for final alignment and welding  |

|

Scooter Doc

Currently Offline

Posts: 294

Likes: 0

Joined: Dec 12, 2011 16:49:03 GMT -6

|

Post by tmec on Jan 27, 2012 9:22:34 GMT -6

how did you do the crossmember for where the bump-stop is on the motor mount?

|

|

Senior Clinician

Currently Offline

Posts: 130

Likes: 2

Joined: Dec 13, 2011 2:27:16 GMT -6

|

Post by new2scooters on Jan 27, 2012 10:13:45 GMT -6

how did you do the crossmember for where the bump-stop is on the motor mount? The rubber on the front part of the motor mount was rectangular shaped so I used a piece of rectangular tubing to "capture" it, but it still allows movement.  |

|

Scooter Doc

Currently Offline

Posts: 294

Likes: 0

Joined: Dec 12, 2011 16:49:03 GMT -6

|

Post by tmec on Jan 27, 2012 10:54:37 GMT -6

and it had rubber on the top and bottom right?

|

|

Senior Clinician

Currently Offline

Posts: 130

Likes: 2

Joined: Dec 13, 2011 2:27:16 GMT -6

|

Post by new2scooters on Jan 27, 2012 11:22:42 GMT -6

and it had rubber on the top and bottom right? Yes, both top and bottom. |

|

Scooter Doc

Currently Offline

Posts: 294

Likes: 0

Joined: Dec 12, 2011 16:49:03 GMT -6

|

Post by tmec on Jan 27, 2012 13:17:12 GMT -6

great i think this will work out just fine  well done where does your welding experience come from? |

|

Senior Clinician

Currently Offline

Posts: 130

Likes: 2

Joined: Dec 13, 2011 2:27:16 GMT -6

|

Post by new2scooters on Jan 27, 2012 15:17:17 GMT -6

great i think this will work out just fine  well done where does your welding experience come from? I got my start in Vocational Agriculture class in high school. I spent most of my study hall time periods in the shop. We had a great teacher and he always gave passes to those that wanted additional shop time.....Any time I could get there, I was there...Got my first welder after high school (1970) with funds I earned from trapping. Was a new Lincoln buzz box I purchased for $80 and was the best investment I ever made. I still have that welder today and it works as good now as then. Only had to repair/replace cables and ends once and lube the fan once. Not too bad for 40+ years of service. I purchased a mig welder a few years ago and that is my welder of choice simply because of its flexibility. I keep the Lincoln not only for sentimental value but because it handles the occasional really thick welding so well. Next week I'm going to do the final alignment on the swing arm. My current plans are to set up the laser so it will shoot vertically through the center of the steering tube, down the centerline of the frame and through the center point of the rear tube. I will align the center groove of the rear tire with the laser so it "should" all be true and track correctly.... Got the grandkids coming for the weekend so will be busy until then. That's the plan! |

|

Scooter Doc

Currently Offline

Posts: 294

Likes: 0

Joined: Dec 12, 2011 16:49:03 GMT -6

|

Post by tmec on Jan 27, 2012 15:22:32 GMT -6

Thats awesome I wish I had learned to weld but I guess its never too late. What is the best method of welding for a new person to learn? whats the easiest to learn? where and how to start?

The bike looks great!

|

|

Senior Clinician

Currently Offline

Posts: 130

Likes: 2

Joined: Dec 13, 2011 2:27:16 GMT -6

|

Post by new2scooters on Jan 29, 2012 20:41:21 GMT -6

Thats awesome I wish I had learned to weld but I guess its never too late. What is the best method of welding for a new person to learn? whats the easiest to learn? where and how to start? The bike looks great! IMO, a standard arc welder is the probably the easiest to use but a wire feed mig welder is the certainly the most flexible welder for light to medium welding projects. Probably the best option for someone that has never welded before and would like to get started would be to find an entry level class such as those offered by Adult Education centers....That way you can try out various types of welders used by the sponsoring school and at only the minimal expense of the class. I would say that a couple of "must haves" are a good pair of leather welding gloves and an auto darkening welding mask. Gloves are about $10/pair and a mask will start at about $35 (Harbor Freight) and go up from there.....My first mask from Harbor lasted about 9 months before it quit working. (Probably my fault as it took a few hard drops....) My second Harbor mask is a couple of years old and is still working fine. Just been a little more careful with this one though. As with a lot of the "Harbor" tools, they work great within their limits.... |

|