Ok, let's get things started!

First I'll show everything I bought so far for these projects.

The wheel balancer:

All of the electronics: (tachometer I had previously bought; might use it as the housing for my arduino, oil temp gauge, relay board I had lying around from a previous computer water cooling loop, DC to DC buck converter w/ voltage readout, stepper motor (I bought 6 of those), arduino nano w/ headers, motor driver board, hall effect sensor board; bought 2 of those, arduino pro mini w/ headers, 0.030mm solder, and jumper wire kit)

All of the plumbing and equipment for the oil cooler: (radiator w/ baggie of mounting hardware, hose that came with radiator, hose bought from local auto store, check valve, transmission "add-a-plug", 1/8" npt female coupler, 1/8" npt nipple, 4x 1/8" npt to 5/16" hose barb adapters, 1/8" npt 4-way, 8x hose clamps, fuel/diesel/oil pump, 1/8" npt bleeder valve, 2x 1/8" npt street elbows)

And the bicycle speedometer: (I actually already had this lying around the garage)

Note that the wiring that is there is not how it came from the factory, that is my doing. Also, I made the reed switch housing.

Now some close-ups of some of the items.

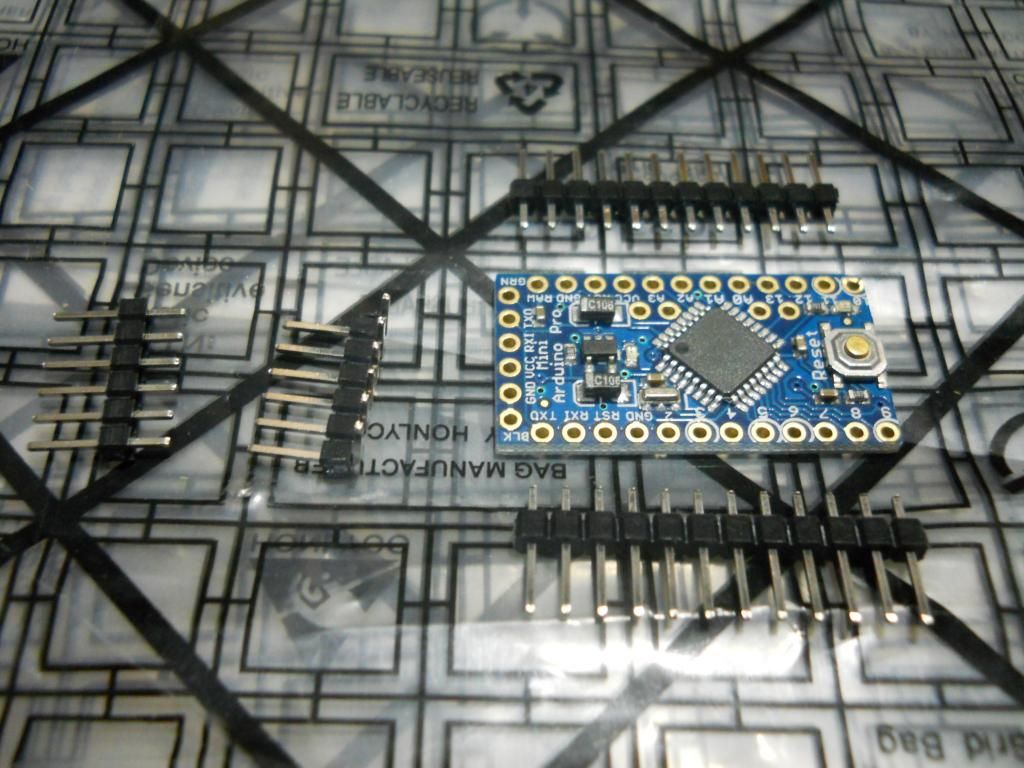

Arduino pro mini:

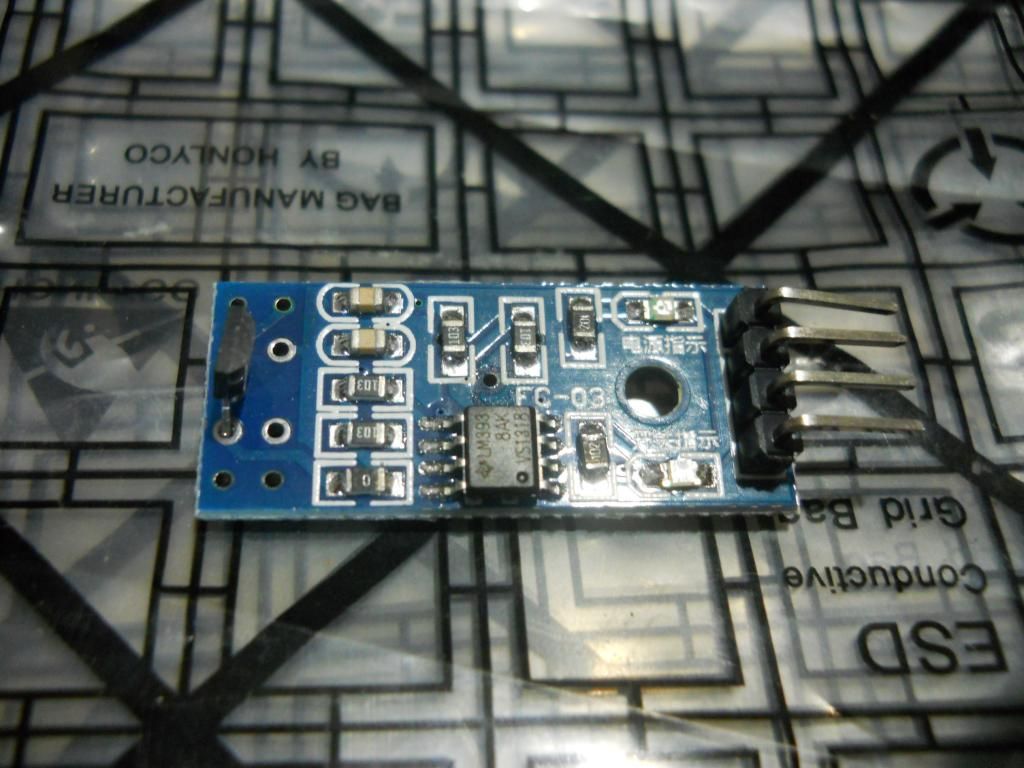

Hall effect sensor:

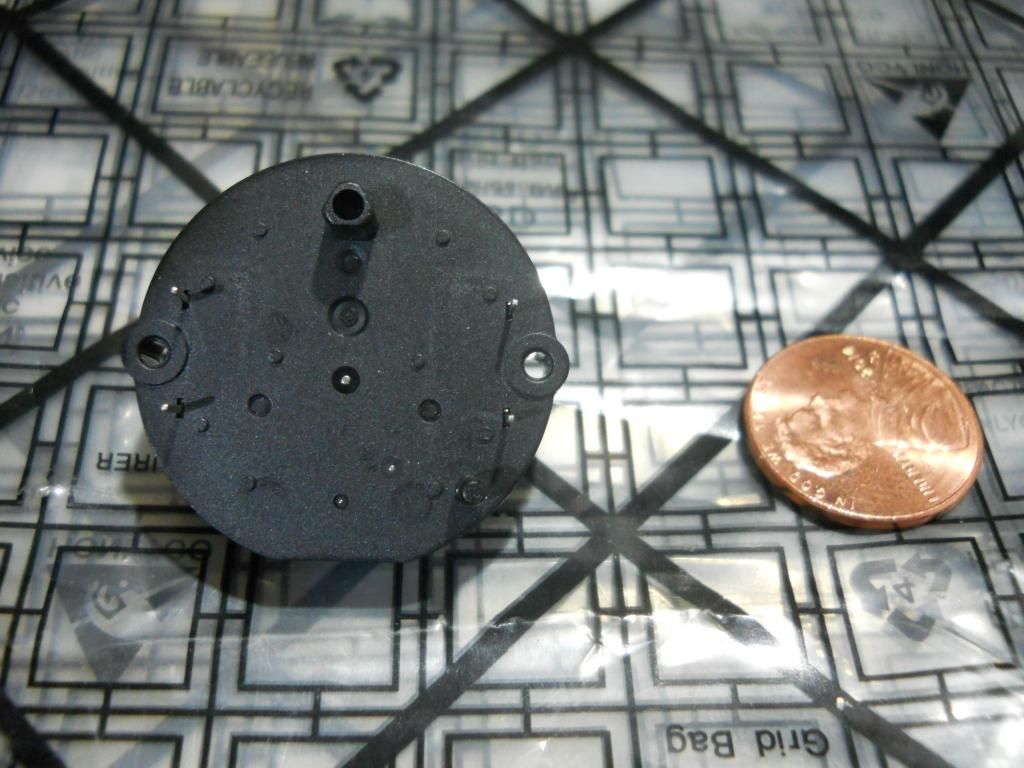

Stepper motor: (penny for size comparison, these things are tiny!)

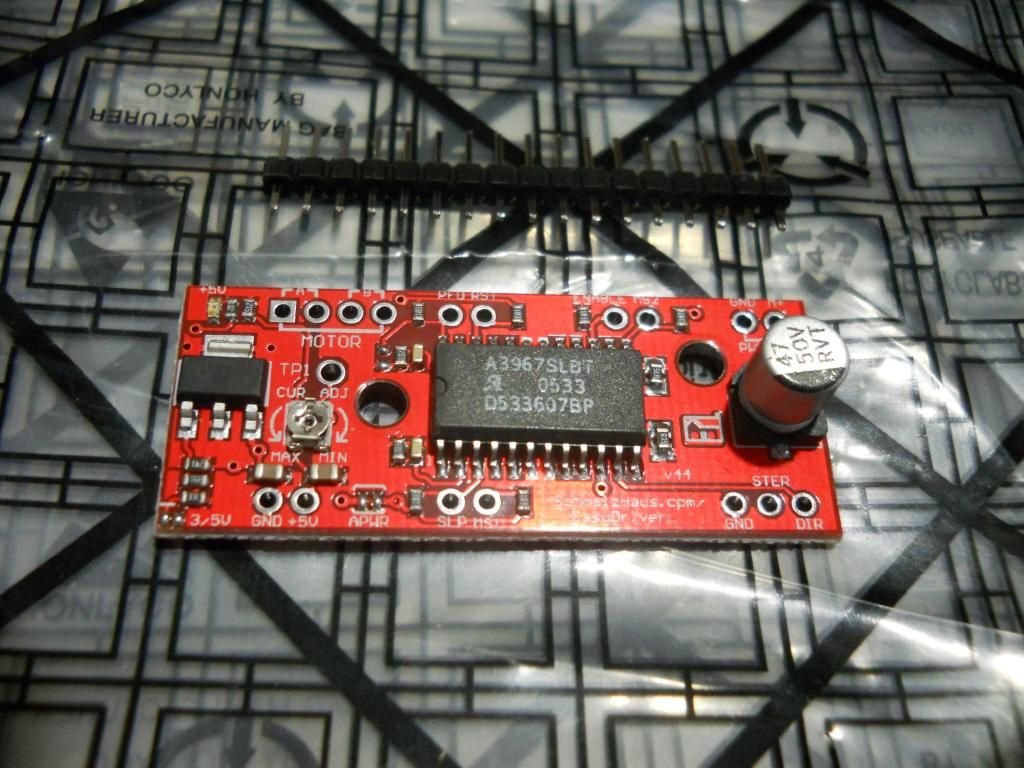

Motor driver board:

Arduino nano: (I bought 2 arduinos because I am fairly certain I am going to end up doing something stupid and end up blowing one of them)

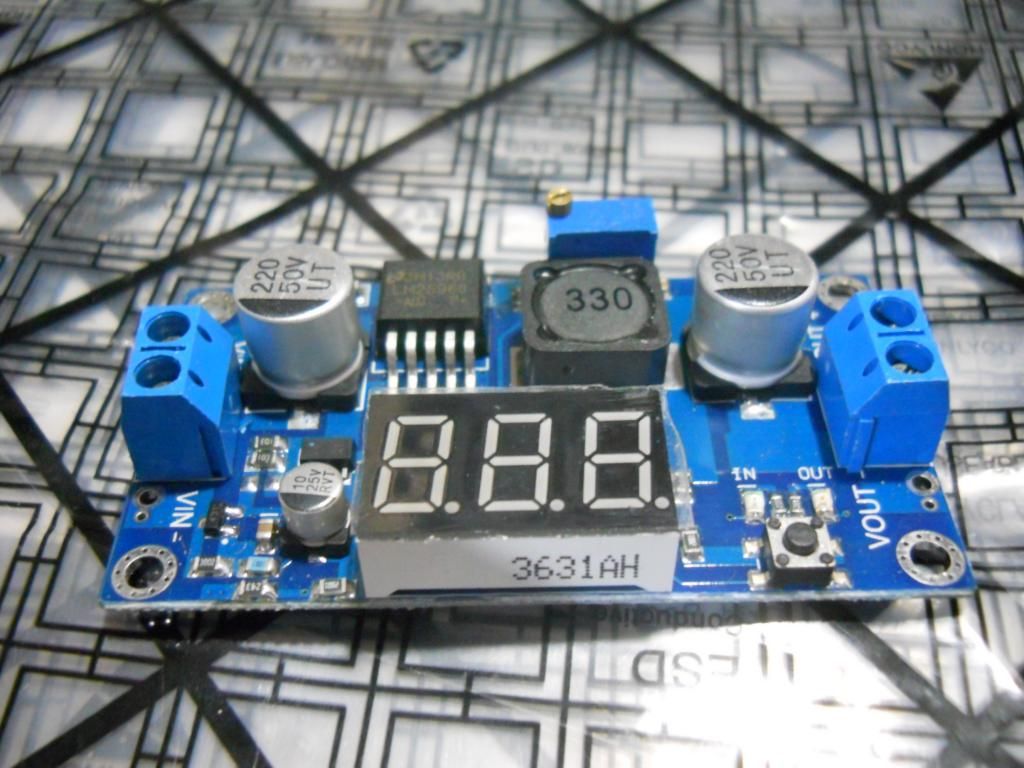

DC to DC buck converter with voltage display: (it's a good thing this had a voltage display because I also bought a separate voltage display module but I'm starting to think it had been lost in shipping)

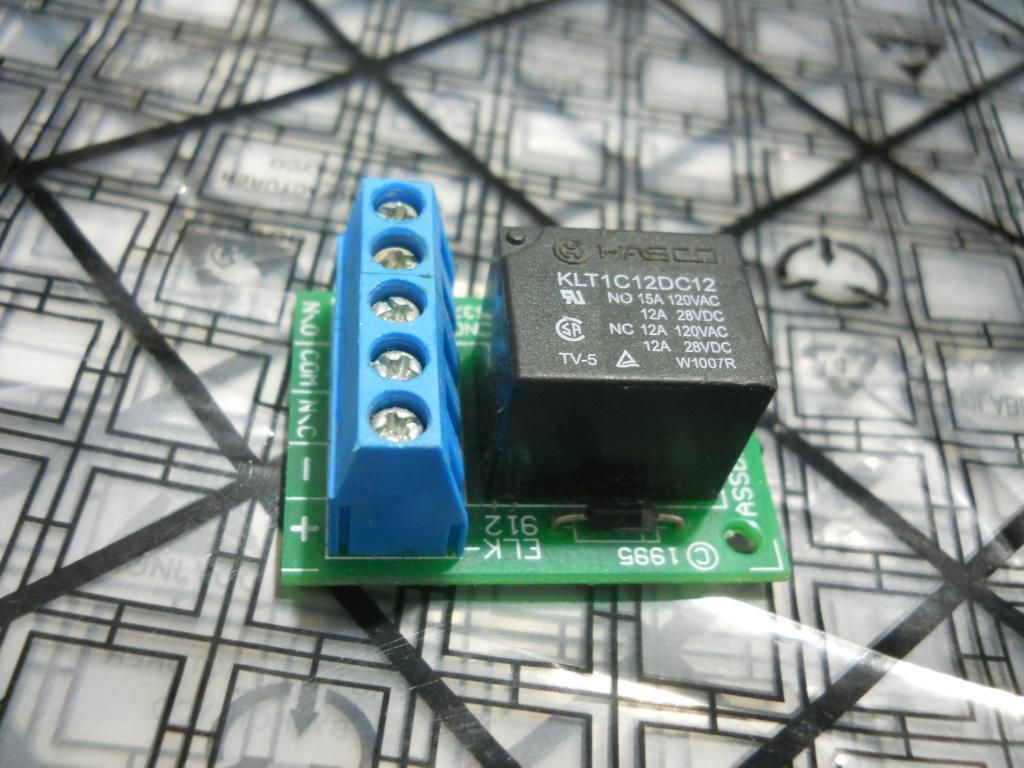

Relay board: (again, I had this lying around because I used it to turn on a water pump when my computer started back when it was water cooled. I'm not sure if I am going to use this board in any of these projects.)

Radiator: (would also make a great cheese grater)

Now that all of that is out of the way, I can start to tell you what I have been doing the past few days.

I started by checking out the wheel balancer. I really wanted to make one myself, but I couldn't find any tapered fittings. Oh well. The rod is, I believe hardened steel. It isn't precision ground, but it is quite smooth and shiny. The bearing holders are made of aluminum and are very thick; at least 1/4". The bearings themselves are 628zz.

One of the bearings I received was horribly scratchy. It wasn't worth it to send it back and get a replacement or refund so I decided to replace them with some common 608zz bearings. I created some mock-up bearings that were the same size as the 608's to see of the steel rod would still rest on two bearings and not touch the aluminum base. Nope, it touches, but I can just grind a little bit of the base off between the two bearings and everything will be hunky dory. Here is a pic showing the difference in size:

I looked online to see the prices for 4 608zz bearings and it was around $15. Luckily one of my local hardware stores had skateboards on sale (skateboards almost universally use 608's and oddly enough my hardware store stocks them). $5 later I had 8 bearings, a deck, some hardware, and 4 skateboard wheels to use.

Now onto the oil temperature gauge.

The sending unit that came with my temperature gauge is a bit bent. The probe that extends out of the threaded part bends slightly to one side. At first this wasn't too much of a problem. My main concern was that the probe was going to stick too far into the 4-way fitting that the bleeder valve I was going to put on the opposite side wasn't going to be able to thread in all the way. That turned out to not be a problem. However a different problem reared it ugly cheese-hating head. the probe, when completely installed in the 4-way fitting, leaves very little room for oil to circulate around it. Here is a pic to illustrate what I mean:

As you can see there is very little room for the oil to flow around the probe. I can still blow air through the fitting if I plug the port opposite the probe, but it is restricted.

I thought about using a 1/4" npt 4-way and a few 1/4" to 1/8" adapters so there would be much more room around the probe. I bought a 1/4" npt male to 1/8" npt female bushing and a 1/4" tee to see if this idea would even be feasible. It wasn't. Because the probe was bent, when I tried to screw it into the bushing, it rubbed against the inside of the fitting, preventing it from being screwed in all the way. I tried drilling out the inside of the bushing and even sanding the probe, but nothing worked.

I returned the tee and the bushing and went back to the 4-way. Since I had sanded the probe a bit I tried to screw it back into the 4-way again and this time, even though I sanded only a little off, the room around the probe improved. It is still obstructing the flow some, but I will have to deal with it and hope the pump I bought will still be able to push oil past it at an acceptable rate.

Next, I was going to test out the probe by measuring its resistance while in air and in some how water. Here is a pic of the probe:

I started screwing on the requisite hardware onto the top electrically isolated threaded part, the when I started to tighten a nut onto it, the entire top threaded portion started twisting. Eek! I should have expected it from a chinese part. I'll just have to be careful with it.

I also have a very similar probe and analog gauge from sunpro. The probe is nearly identical externally, except for a longer length and a top threaded portion that won't twist. The resistances at room temp aren't the same, though. The sunpro is about 2.5k ohms, and the chinese one is about 1.5k ohms. I doubt that they are compatible, but perhaps for snits and giggles I will test both probes on both gauges and see what happens.

All of today and a little bit of yesterday I have been working on a wiring harness for all of the components I plan on adding. Here is a pic showing an unorganized mess-of-a-harness-in-progress:

And yes, that is my bed. I have been known to sleep with electronics. And computers. When I have projects like this, by bed becomes temporary storage space and my computer desk becomes by work bench.

That's all for tonight, my fingers hurt. Goodnight all!