Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Aug 4, 2014 9:48:06 GMT -6

I rode my scoot to a doctor's office today. No mechanical maladies to report. I cruzed along at around 25 mph the entire way there and the oil temp only got to about 60c or 140f. Oddly enough when I got home I left the engine idling in the driveway so I could listen to it with my stethoscopes and the oil temp got up to 90c or 194f. I'm guessing the lower speed of the engine and thus the fan on the flywheel means less cooling. First I probed around the engine with the mechanic's stethoscope and found that the tick isn't incredibly clearly audible in any location that I probed, but it was at least noticeable in two places - the bolts that hold the intake manifold on and just above the oil filter drain, next to the oil fill and dipstick hole. Next I tried the real medical drum-type stethoscope. Man is this thing good! I can hold the drum a foot away from the cvt or engine and hear it clearly. I tested most of the same areas, although some I couldn't test because either I couldn't fit the drum in a tight space or I would have burned myself holding it there. The same places; intake manifold bolts and above the oil screen drain, I could hear the ticking sound. I recorded a video right after I was done probing the engine. You can hear the ticking best when the camera is pointing at the carburetor. Here is a video showing the fuel pump in action. I tested the amperage draw on the pump - it went between 0.3A to 2.1A, averaging about 1.6A. Yesterday I went to the local flea market and almost bought a timing light, dwell/tach meter, and a vacuum/compression/cylinder leakage gauge, but I thought I better save my money in case this ticking is something serious. |

|

|

|

Post by Bashan on Aug 4, 2014 19:12:25 GMT -6

Well that's definitely a diaphragm pump there's no doubt about that! It sounds like valves to me, set them. Also check for an exhaust leak at the header pipe to head. You have a gasket in there?

Did I miss a step? You have the cooler running now with the pump? At idle the bike gets hotter because the OEM oil pump is purely mechanical and less oil is moving at idle. That means less oil down the cooling tower "cam chain tunnel". The fan is also spinning slower. These bikes use the oil for cooling to a huge degree.

|

|

Senior Clinician

Currently Offline

Posts: 153  Likes: 2

Likes: 2

Joined: Apr 3, 2014 15:10:43 GMT -6

|

Post by genseeker on Aug 4, 2014 23:22:24 GMT -6

beautiful calico you have

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Aug 5, 2014 8:03:25 GMT -6

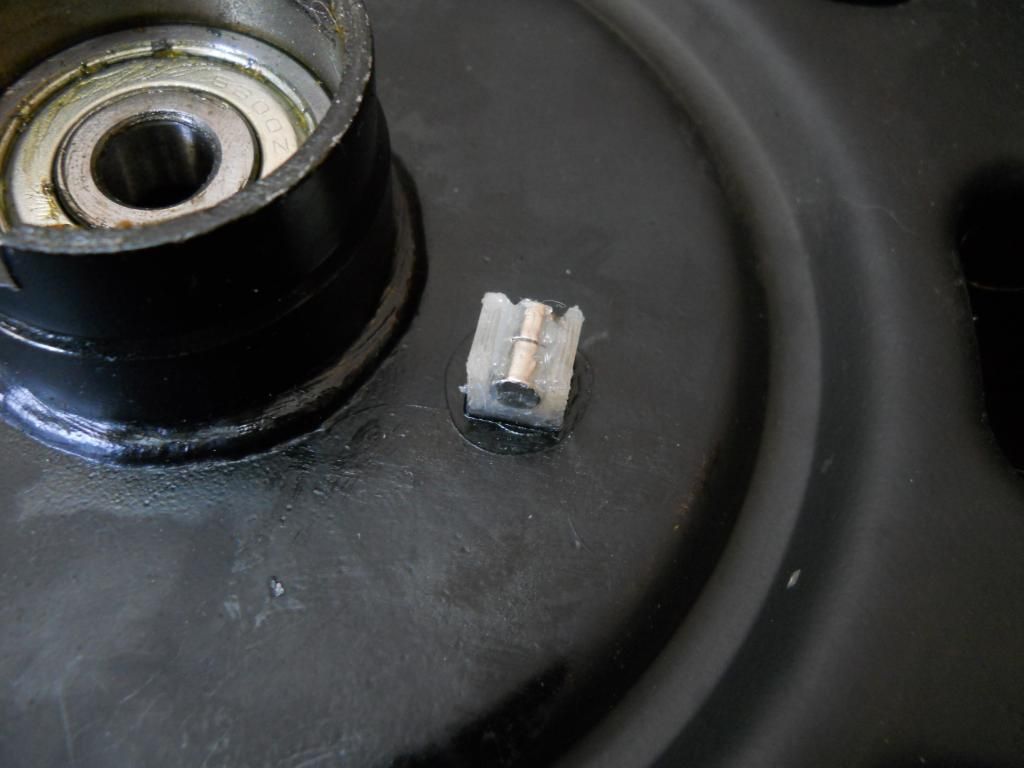

I do have an exhaust gasket... kinda. The first time I took off the exhaust from the scoot I noticed the header flange wasn't flat at all. If you held a flat edge against one bolt hole, there would be about a 1/4 inch clearance between the other bolt hole and the flat edge. I reused the old metal and organic material gasket plus some high temp copper silicone sealant. I could try and bend the flange back to being close to straight, but I'm afraid I'll crack or break the welds joining the flange to the pipe. I do have a tiny little 80 amp stick welder, but have almost no experience welding, plus I'm pretty sure that 80 amps isn't enough for the thick flange. Yes, I am going to run the cooler with a pump. Thank you for the compliment on my cat. I do love her, even though she bites my nose in the morning and meows for hours in the middle of the night when she wants to be let inside. Yesterday I realized that the reed switch holder I made for my bicycle speedo wasn't going to work, so I designed and made a new one that will straddle the speedo puck and hopefully stay put.      I tried to record some of the printing, but my camera's batteries died right after the first layer. I also noticed that my scooters wheels won't fit on the metal rod that came with the wheel balancer. I had some precision ground rods that I salvaged from taking apart printers lying around and found one that will work. The rod is MUCH smoother than the one that came with the balancer. I had to grind away a bit of material from between the bearings so the rod won't touch the bearing holders.   Now I just need to design and make some cones sized for that rod so I can balance my wheels. It did rain all last night and is still drizzling outside so no riding today, but I might try and figure out how I'm going to mount the radiator. Later dudes. |

|

|

|

Post by Bashan on Aug 5, 2014 17:43:38 GMT -6

For some reason it sounded like you had started using the cooling system but I didn't see it on the pix....my bad. I guess because you talked about the amp draw on your pump. I'm thinking I might try something similar on my SYM but instead of a cooler I want to do a spin on oil filte or inline filter. Just draw from the 17mm on the left side, through the filter, and into the valve cover. It wouldn't interfere with the regular oil delivery and would be removed from all of the systems but the electrical. Just out one side and back in on the top. Low volume but I think it would do much better than the basket screen. Can you model a small version of Cyborg's head? Oh wait...it's already microcephalic....never mind.

|

|

|

|

Post by cyborg on Aug 5, 2014 19:21:08 GMT -6

Hardeefukingharhar,,,, GOD YOU'RE FUNNY!!!!!!! You'll wow them on the moon Alice ,,,,,

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Aug 5, 2014 20:04:07 GMT -6

I've been toying with the idea to add some kind of filtration to this setup; I could hollow out an aluminum shell similar in shape to the check valve I have and add some very fine metal mesh - 100 microns or less, or I could use a filter intended for fuel that doesn't have any or too many plastic parts that would melt; perhaps something like those visu-filters that have brass elements in them. Let me see if I can find a pic of one...  I would avoid any that use plastic mesh or paper filters - I have a feeling those would either melt or clog and severely limit flow respectively. Yeah, I was testing the current draw of the pump to see how much if any headroom I will have with it installed and running. I think I can safely draw up to about 2.5 maybe 3 amps before charging voltage takes a dive. On a side note and a wee bit off topic; the pump consumes the same amount of power pumping oil as it does running dry. Just a stray tidbit of info I had. I would gladly model Cyborg's head but I am no good at modeling organic things, only mechanical parts. |

|

|

|

Post by Bashan on Aug 5, 2014 21:09:14 GMT -6

|

|

|

|

Post by Bashan on Aug 5, 2014 21:22:17 GMT -6

I used this paper filter and it did fine:

Here it is up to temp with the pump running:

I think it's a lot better to use something designed for oil and oil temps but the design tolerances on things for the engine are pretty broad. For instance, a fuel filter is designed to be in that hot engine compartment in it's worst case scenario position.

|

|

Doc's Anything Goes

Currently Offline

Posts: 1,226

Likes: 81

Joined: Apr 4, 2014 3:52:42 GMT -6

|

Post by richardv on Aug 6, 2014 3:09:53 GMT -6

I'm watching this with much interest but you may keep the blue cheese. Colby or sharp Cheddar for me. I can see the use of a lot of street rodding components with this set-up but would hate to find out the cost.  |

|

Doc's Anything Goes

Currently Offline

Posts: 1,226

Likes: 81

Joined: Apr 4, 2014 3:52:42 GMT -6

|

Post by richardv on Aug 6, 2014 7:30:07 GMT -6

How are you connecting the pump electrically? I would think the most efficient would be to have it turn on when the oil reaches an operating temperature.

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Aug 6, 2014 9:32:23 GMT -6

Thanks bash, I'll look into those oil filters. Or perhaps one that doesn't cost more than the entire cooling project.

I designed this project to be as cheap as it can be. The parts for just the oil cooler assembly (not the arduino stuff), including all requisite hardware, fuel lines, fittings, pump, etc can be had for about $80. When I am completely finished I will post a complete BOM of all hardware being used in the system so anyone else who wants to do a similar project doesn't spend any money on something that they won't need or that won't work or break.

I have the pump connected via a toggle switch as well as a blade fuse. In theory, I could use the arduino to turn the pump on and off at a preset temperature.

For most people it is either love or hate for blue cheese, there seems to be no middle ground. When I was little my father used to take me to a store that sold nothing but wine and cheese and I guess that is where my addiction started.

|

|

|

|

Post by Bashan on Aug 6, 2014 13:43:11 GMT -6

Wow, that was expensive, I didn't even look at the price. Well, at the other end of the universe, try this page. I know, I know, oil injection filter, it's not hot oil, something to think about:

|

|

|

|

Post by cyborg on Aug 6, 2014 17:53:43 GMT -6

Crumbled blue please on my salad with grilled chicken breast

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Aug 7, 2014 9:40:07 GMT -6

Not too much has happened in the past few days as far as the scooter goes; I made my mother some lasagna, and have been helping her with her new laptop. Today, I installed the reed switch onto the speedo puck and glued a magnet to the front wheel.   Now I'm going to (if I don't get distracted again and start daydreaming about cheese-injected sausages) model and make cones for the machined rod I am going to use for the wheel balancer and hopefully balance at least the front wheel. I SWEAR I am going to get to mounting the cooling loop soon. It seems like I am jumping around all over the place with micro-projects and not getting to the heart of why I made this thread in the first place. |

|