Doc's Anything Goes

Currently Offline

Posts: 1,226

Likes: 81

Joined: Apr 4, 2014 3:52:42 GMT -6

|

Post by richardv on Sept 18, 2014 4:27:24 GMT -6

In model rail roading we use isopropyl alcohol to remove paint. It is friendly to plastic and glue. Give a 10 minute soak and scrub off the paint with an old tooth brush. It may take a few go rounds. If you have Rubbing Alcohol that would work. It has oils in it for lubrication which is bad for painting though. It's also good for cleaning electronics.

If you can't get in with a tooth brush get a stiff artist brush and cut the bristles off short.

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Sept 18, 2014 10:23:22 GMT -6

I use 91% isopropyl alcohol to clean my print bed of all dust and oils before each print, so I have a bunch of that lying around. I'll give it a try.

The second print finally finished around 2:45 am last night. After cleaning up all of the support material, it looks pretty good.

Either the first or the second piece was printed with sides slightly like a parallelogram; the sides on one axis line up but the other sides don't. I'll do a once-over on the printer to make sure all the screws and tightened and possible print a few calibration pieces before going on to the final piece of the airbox.

It is looking quite dreary outside; heavily overcast, roads are slightly wet, and there is a fine mist continuously raining down. Most of the electronics on my scoot aren't waterproof or water resistant. Some of them aren't even weather resistant. I might be able to manage one or two runs with different variator weights if the mist coming down stays a mist and doesn't turn into a downpour.

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Sept 18, 2014 14:46:52 GMT -6

No luck with the alcohol. Oh well, the yellow tint doesn't bother me too much. Here's what the sharpie marks on the variator look like after a top speed run with the stock 5g weights in the variator:  As you can see, I still have 3-4mm left of belt travel. I took the stock 5g weights out of the variator and put the "5g" (more like 5.3g) koso weights in. Acceleration improved very slightly. Top speed without tuck with a head wind was 40 mph. TS without a tuck and a side/tail wind was 42.1 mph. TS with a side/tail wind and tucking was 44.1 mph.  I was only WOT for about a minute while not tucking and I only tucked for about 15 seconds, so the scoot may go a wee bit faster than that. Here's the sharpie marks after the top speed run with the koso 5g weights:  To me, it looks like the belt was riding just a little bit higher with the koso weights. I'm going to wait for my extremities to warm up and the cvt to cool down before putting the 6g weights in. Right after I finish this post, I'll start printing the final piece of the airbox. |

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Sept 20, 2014 0:07:47 GMT -6

All of the pieces of the airbox are finished printing and are either being glued together or having silicone sealant applied to them so they can be tightened together with bolts.

I put the 6g weights in the scoot and had some conflicting results. When I went out on the same route that I tested the stock and 5g koso weignts, I only got 37 mph with no tuck and no wind; with a tuck facing a different direction, I got 42 mph.

Halfway home from that test I DOH!! ran out of fuel and had to walk the scoot home about 2 miles. It wasn't too bad. I walked to the local gas station and bought 2 gallons of premium gas and went back home and filled the scoot back up to the brim.

After that I went to that car dealership giveaway thing that I said I'd go to yesterday. I did get a $5 gift card out of it; just enough to buy some cheese!

A few of the roads between my house and there have 40 mph speed limits, so I was assuming I was just going to get passed by everybody and everything. Quite the opposite. I was managing to top out at 45 mph without a tuck! At those speeds, according to my chinese tach, the engine was turning 8k rpm which I don't think is too high for these engines or high enough for valve float to occur (fingers crossed). The acceleration was improved a bit more, too. I think for now I'll leave the 6g rollers in. I haven't yet taken of pic of the variator drive face with the sharpie markings yet, I'll do that tomorrow.

After that I went to a pharmacy to pick up some medications that keep me sane and able to function in social situations. As I pulled up a guy parked next to me and asked what all I had done to the scoot. I explained everything to him and then he inquired to the cost of the oil cooler radiator. When I told him $25 he was in shock. I told him to search ebay for an transmission cooler assembly and he could probably find one for $25-$35. He said he has a scoot of his own that had a BBK on it and that I would probably see him around town on it.

I didn't really notice that the ride was any smoother, but it wasn't bumpy. As the old saying goes, things that are working perfectly and as they are intended go unnoticed; things that are breaking or have broken get noticed much more easily.

Nothing much else to report.

Edit:

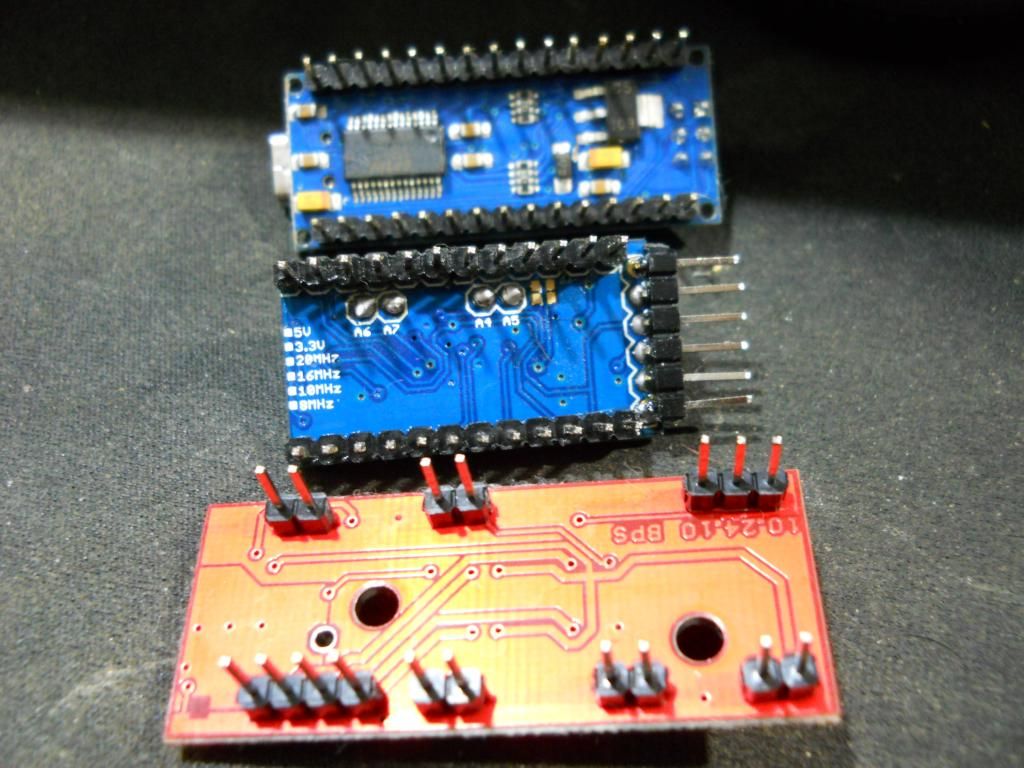

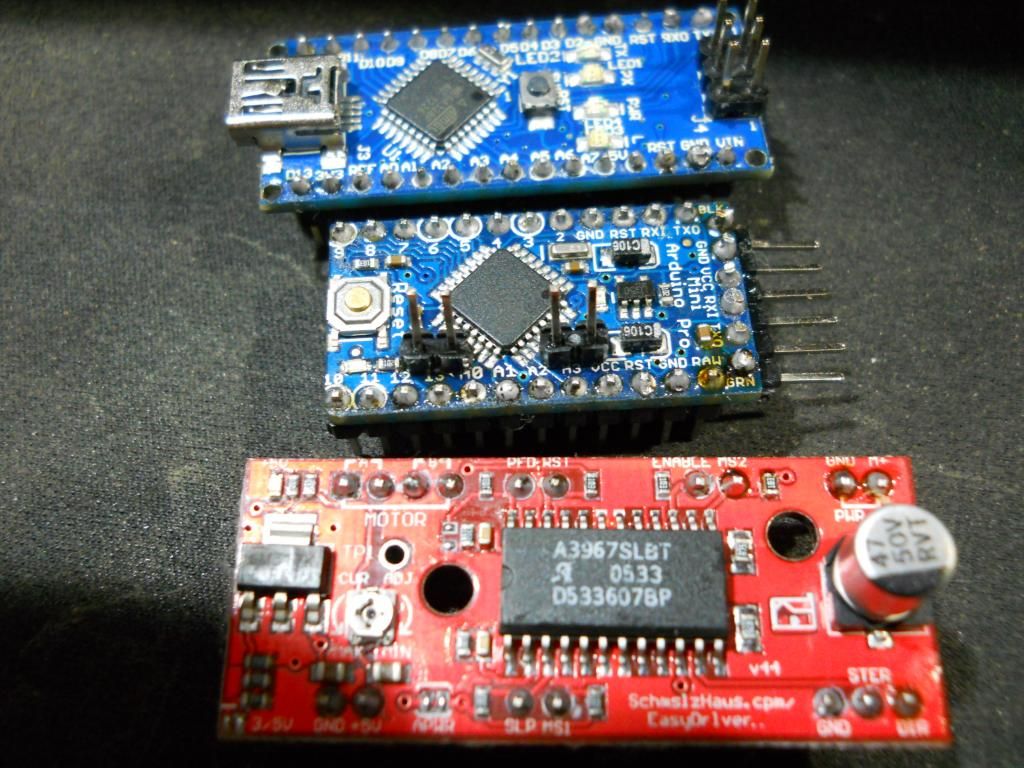

Oh, I also soldered all of the header pins to the arduinos and the motor driver board. I'm glad I bought some very fine diameter solder.

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Sept 20, 2014 16:40:32 GMT -6

The airbox was an abysmal failure. Despite all of the measurements I took and range of motion of the engine vs the frame, it just didn't work out. Oh well. Today I went our for a ride to the local flea market and for once didn't buy anything. When I want back to get on my scooter a man confronted me and told me I "sure am courageous; people don't see motorcycles, I can't imagine what it much be like on a scooter". I told him I had a read loud engine and that I keep my headlight, which is brighter than the stock one, always on. After that I went to the grocery store to pick up a very small selection of items that I could hang from the bag hook on the scooter. As I came out (I had secured my scooter to the bike holder frame) an older man inquired about my scooter, how much it costs, and how fast it went. I took the groceries back home before heading out one last time to a hardware store to get some bolts and nuts to tighten up where the handlebars meet the steering stem. Just as I pulled up next to the bicycle rack, on of the younger parking lot attendants said some stuff along the lines of, "dang man, you sure got that thing pimped out. What kind of mileage does that thing get? How fast does it go? What size is the fuel tank?" Of course I answered all of his questions. It's really different for me having people come up to me, initiating a conversation, and asking me questions. While I was in the hardware store I heard what I assumed was a big crack of lightning followed by a roll of thunder. In my mind I said,(in a cartman voice) "screw you guys, I'm going home." I JUST missed a downpour be about 3 minutes. I was able to get the scoot up to 45 with little-to-no wind and got it to slowly climb to about 39 with a head wind. Oil temp never went above 75C (167F). The tire balancing beads seem to be doing their thing. Here's a pic of the sharpie marks on the drive face after a top speed run with the 6g weights:  I can barely tell any difference between the stock, 5g koso, and 6g koso weights. Also, here are a few pics of the header pins I soldered onto the arduinos and motor driver board. Don't worry, I cleaned off all of the flux residue:   I'm off to eat an overly-large turkey and dumpling dinner and take a nap. |

|

Doc's Anything Goes

Currently Offline

Posts: 1,226

Likes: 81

Joined: Apr 4, 2014 3:52:42 GMT -6

|

Post by richardv on Sept 20, 2014 19:35:06 GMT -6

I wish I knew more about the electronics but I lost interest after my company right sized in 2002, just too busy looking for work, and there's a lot more available now. Maybe I'll have time after I finish what I'm involved with now. It's good to hear most every thing is working well. I believe you will find and answer for that air box. And if you continue going around with that big smile on your face, a lot more people will want to say hello. Trust me it works better than a frown.  |

|

Doc's Anything Goes

Currently Offline

Say no to scooter abuse

Say no to scooter abuse

Posts: 3,873

Likes: 156

Joined: Mar 31, 2010 19:07:16 GMT -6

|

Post by jct842 on Sept 20, 2014 22:05:41 GMT -6

I have been wrong on a few occasions but I am pretty sure the red line is a theoretical number based on a particular engine and then of course how it gets rid of heat. As rpms go up the heat goes up at a must faster rate.

|

|

Ad Free Donut

Currently Offline

A bike is music to my ears.

Posts: 1,655

Likes: 93

Joined: Oct 22, 2013 4:11:04 GMT -6

|

Post by Guitarman on Sept 20, 2014 22:39:21 GMT -6

See, Scootering, or riding on 2 wheels in general, is good for your mental health.

Before you print another anything, make one out of cardboard and see how well it does. Make all your changes in cardboard until you have a (mostly) final design. Then spend the $$ to print. That filament has got to be costly.

Duct Tape and cardboard is the Handymans' secret weapon.

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Sept 21, 2014 0:28:18 GMT -6

I'm aware that on these scoots, at least on ones without limited CDI's, there isn't a rev limit like on a car, you just go as fast as you can go until either the valves start to float or other things start to break, similar to a 2T. Yes, I really should have made a model out of cardboard first like I did with the seat frame, but I was in such an eager mode, my brain wouldn't let me pull away from the modeling software. The filament doesn't cost too much; on ebay if you can find 1 Kg (the usual standard amount) for $20-$30. Other places such as printrbot's website and other websites of companies that make printers typically charge $35-$45 per Kg, not including shipping. The hard part is finding a cheap dealer that has filament that is uniformly round, not ovaled, has a diameter of ~ +/- 0.03mm, is made virgin material, and will extrude when heated through nozzles as small as 0.1mm without clogging. I think all mass produced filament is made in china, except for a very few number of small businesses or groups of people who have built their own filament extruders. If I could afford a filabot I would make my own filament at close to 10x cheaper costs than ordering filament online. I just had jet another crazy idea as I was riding today. I noticed that every time I wanted to check my speed/rpms/volts/oil temp I have to look downward and away from the road. What if I mounted something like a miniature 7 segment display inside my helmet that would reflect off of the visor and give me a heads-up display of whatever parameter I choose to display? On a different subject, you can probably tell that when you compare the three pictures of the sharpie marks on the drive face with the different weights, the distance to the outside edge only changes very minutely. Is this the design limit of the stock variator or should I be looking into even heavier weights? Also, without spending money on weights that may or may not work, can I do something like put a few metal BB's in the middle of the weights to add weight or will they just go flying around inside the variator and cause havok? |

|

Ad Free Donut

Currently Offline

A bike is music to my ears.

Posts: 1,655

Likes: 93

Joined: Oct 22, 2013 4:11:04 GMT -6

|

Post by Guitarman on Sept 21, 2014 1:16:15 GMT -6

All the extra weight does is get you moving faster. It can actually take away some of your top end.

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Sept 21, 2014 10:43:48 GMT -6

I read all the how-to articles on this forum regarding cvt tuning and I have come to the (possibly wrong) conclusion that since there is very little difference in the sharpie marks between the 5g, 5.3g, and 6g weights; the weights are pushing out on the variator and traveling as much as they can. Perhaps this stock variator doesn't allow the belt to ride up all the way to the top of the ramp.

I have been told that since I installed a BBK, my power band will drop to a lower rpm; that is why I have been trying the heavier weights. Right now, with the 3 sets of weights I have, the engine runs between 6500 and 8500 rpm. If the power band is higher than that, I will need lighter weights.

I'm pretty sure the only way to find the power band of the engine, short of a dyno run, is to buy different weights and try them.

Please correct me if any of the above stuff is wrong.

|

|

Doc's Anything Goes

Currently Offline

Say no to scooter abuse

Say no to scooter abuse

Posts: 3,873

Likes: 156

Joined: Mar 31, 2010 19:07:16 GMT -6

|

Post by jct842 on Sept 21, 2014 11:38:04 GMT -6

On a different subject, you can probably tell that when you compare the three pictures of the sharpie marks on the drive face with the different weights, the distance to the outside edge only changes very minutely. Is this the design limit of the stock variator or should I be looking into even heavier weights? Also, without spending money on weights that may or may not work, can I do something like put a few metal BB's in the middle of the weights to add weight or will they just go flying around inside the variator and cause havok? As far as the belt going up higher you could try running it up on the center stand but am guessing that you have already reached the limit of the variator. wider belts can go higher and so can some variators. edit: try taking the variator off and and shove it together, then stick the belt in it to see where it would ride. |

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Sept 21, 2014 22:28:13 GMT -6

As far as the belt going up higher you could try running it up on the center stand but am guessing that you have already reached the limit of the variator. wider belts can go higher and so can some variators. edit: try taking the variator off and and shove it together, then stick the belt in it to see where it would ride. I can't run the engine on the c-stand with the cover off; the starter bendix is held in place by a bushing in the cvt cover. The bendix would be loose and clash with the teeth on the edge on the variator. If I really wanted to I guess I could use an electric drill or a ratchet and spin the variator nut by hand. I think I know what you mean by, "taking the variator off and and shove it together, then stick the belt in it to see where it would ride". I"ll try that tomorrow. I'm debating on getting a koso variator from NYC scooter parts. I'm also thinking abut sliders vs rollers but since my variator is begged out right now It won't make any difference switching between the two. I'm quite happy with how my scoot accelerates up hills, so I'll leave the contra spring alone for now. |

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Sept 22, 2014 19:03:36 GMT -6

I didn't get to do any work on the scooter, but I did ride it to a protest so I could get some practice taking pictures with my camera. I had a camera bag that fit my camera body and both of my lenses, but I also had a tripod and no way to securely transport it with me on the scoot.

I went all over town looking for the cheapest backpack I could find that didn't look like something disney barfed up. Geez these things are getting expensive; The lowest priced backpack I could find that wasn't on sale/clearance/marked down was $35! I managed to find one at a department store that was 50% off for $10. It had bungie cords on the front of it so I could strap the tripod down, put the camera bag in the back pack (a bit redundant, I know), and bring a few water bottles.

I took about 65 shots, maybe 40 of them good. Without revealing too much info, I was requested to take a picture of someone which might eventually be published in the newspaper.

As for arduino related stuff, I'm testing out the motor driver with a few stepper motors I salvaged from printers I had taken apart. If you are into electronics and need/want cool components, take apart printers. I have countless springs of every imaginable size and shape, 2 dc motors with opto-encoder wheels, IR emitter and detectors to go with the encoders, cold cathode lights with power supplies from scanners... the list goes on and on.

One small potential problem I foresee is that the motor driver board can only deliver current as low as 150mA/phase, but the small gauge-motors I bought use at the very most 40mA/phase. Maybe something like a resistor in series with each phase to limit the current.

|

|

|

|

Post by Bashan on Sept 23, 2014 8:48:54 GMT -6

Does your variator have a washer between the two pulleys? If so that's a restrictor and can be removed.

Do not put BBs in the variator.

The heavier weights push harder on the inner pulley and theoretically get you more top end. However, if the engine isn't powerful enough it simply cannot handle the higher ratio. Therefore, it's self limiting and the engine can't get enough RPM to push the pulley all the way out. You would know this because your RPMs would be less at WOT but the top end would be the same or actually lower. This would be dependent on your variator not being restricted. My impression is that it is restricted and I see no difference in the amount of belt travel.

|

|