Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 30, 2016 12:50:08 GMT -6

Shouting won't help here. Most if not all of your questions can be answered by searching this board. If you still have a question, as jct asked, you need to provide the motor number stamped on the engine near the kickstand. We can't help you without it. So let's start there, what is the motor number stamped by the kickstand? We are looking for the number like in this pic.  Jim |

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 21, 2016 14:20:44 GMT -6

I think he did that Cyborg... Yeah, float needle not opening enough, maybe some crud in there gumming up the works.

|

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 21, 2016 12:03:10 GMT -6

Re-clean the carb and replace the fuel filter and all fuel lines. Fuel lines can deteriorate from the inside and the bits of rubber can clog the jets, esp the idle jet.

|

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 18, 2016 22:49:56 GMT -6

Unless it's something really wonky, it should use the same jets that they all do. I haven't seen one that didn't myself...

|

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 18, 2016 14:29:42 GMT -6

parsonsj11 I've got one of Scrappydog's 30mm pumper carbs I ordered on a whim and and found it wouldn't fit my scoot. Brand new, never had gas in it. Not sure if that's the right size for you though... I'll sell it for $90 plus shipping if you want... PM me...

|

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 10, 2016 8:46:42 GMT -6

If your carb looks like this:  You loosen the nuts clamping the cable to the bracket, take the outer nut (closest to the end of the cable) and run it all the way off so it's hanging on the cable. Slide the cable housing out of the bracket via the notch. Unwrap the cable from around the throttle cam and slide the lead end of the cable out of the cam. Installation is the reverse of disassembly. Jim |

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 9, 2016 9:21:30 GMT -6

So I have to relate a quick story. I was having issues with the performance (blue) CDI I've had for years, once I put on a 58.5 BBK on my 150. Hard starting, kickback when kick starting, etc. I went thru the threads here and found Alley talking about the CDI that John sells that actually advances the timing with RPM. Ordered it, got it in a couple of days. But I had a hell of a time trying to get it working. Finally decided to call NYC directly even though it was after normal business hours. I was surprised to have John answer the phone directly! After getting over my surprise at a real person answering the phone I described my issue and then John started suggesting things to test. We spent at least a half hour on the phone, with me and my trusty multimeter testing everything we could think of. We did finally determine that the CDI he sent was faulty and, while we were on the phone, he grabbed a new one, slapped it in a box and printed a shipping label. I got it a couple of days later and WOW, what a difference. No more kickback and as good or better performance as the blue one! I can't say enough about the personal service and integrity he showed. Thanks again tvnacman ! Jim |

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 9, 2016 8:52:25 GMT -6

Just an update to all, I have not had the problem recur, but I also haven't let the tank get below 1/4. So it was either related to needing the exhaust valve a bit looser or just not enough gas in the tank...

Thanks for all your suggestions!!

Jim

|

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 7, 2016 14:16:38 GMT -6

I agree the hose looks like a vent, but it appears to be connected on the other end to the airbox??? Doesn't make sense.

Where is the hose coming off your valve cover going?

|

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 7, 2016 12:50:33 GMT -6

Don't know about the spacer, the hose should be for the valve cover breather?

|

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 6, 2016 16:33:33 GMT -6

Naw, that one should be OK... Oh and richardv that's the secret of all electrical devices. They run on "Magic Smoke"tm . If you let out the smoke, they don't work no more... |

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 6, 2016 6:52:33 GMT -6

Some lighter clutch springs might help that. As the clutch spins, at low revs the clutch springs resist the centripetal force and keep the clutch disengaged. As you rev higher, the springs lose the battle and the weighted clutch pads engage. Lighter springs should lower the rpms that the clutch engages at...

|

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 5, 2016 20:04:48 GMT -6

If you are trying to drive slowly enough that the clutch isn't engaging fully, yeah, your clutch pads and bell may be glazed up. Pull the bell off and take a look, take some fine sandpaper to take the glaze off.

And try not to drive at that speed, you wouldn't try to drive a manual trans car with the clutch half depressed, would you? Except here you control the clutch with the throttle...

|

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 5, 2016 19:51:55 GMT -6

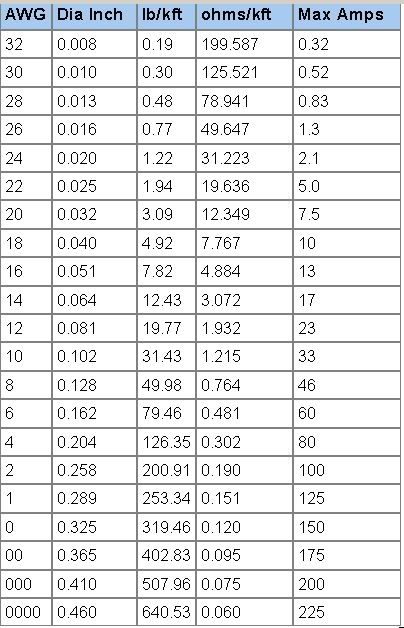

I'll throw my 2 cents in to confuse the matter further... You always want to use a fuse slightly larger than your expected maximum load. And smaller than the current rating of the wire you are using. You don't want the fuse to blow under normal loads, and you want it to blow before the wires start self-destructing. This chart shows about where they will fail...  |

|

Certified Clinician

Currently Offline

Posts: 69

Likes: 6

Joined: Apr 21, 2010 22:19:35 GMT -6

|

Post by thecableguy on Jun 3, 2016 22:26:57 GMT -6

No, you need to take it to a machine shop. They've got the proper hydraulic press to do it without damaging it.

|

|