Senior Clinician

Currently Offline

Posts: 212

Likes: 2

Joined: Jun 1, 2011 16:30:33 GMT -6

|

Post by cdoublejj on Apr 2, 2015 23:42:37 GMT -6

how cam you can just wire up a tack like one normally would instead of making your own? or is it all just for fun?

|

|

Doc's Anything Goes

Currently Offline

Posts: 1,226

Likes: 81

Joined: Apr 4, 2014 3:52:42 GMT -6

|

Post by richardv on Apr 3, 2015 5:24:13 GMT -6

It's even fun watching him do it. If your so inclined.

|

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Apr 3, 2015 14:03:26 GMT -6

how cam you can just wire up a tack like one normally would instead of making your own? or is it all just for fun? For me, it's 1/3 fun, 1/3 necessity*, and 1/3 teaching my self something new. *When I was looking for a tach for my scooter, I had searched all over the internet for a smallish tach for motorcycles, ATVs, snowmobiles, and the like that wasn't digital and would work with a 4-stroke engine with wasted spark ignition (one spark per revolution) for under $50. The only one that I could find was the chrome one that I took apart on the previous page. I had the tach that I took apart previously hooked up to my scooter, and it worked like it should (meaning when the engine was turning at 5000 rpm, the tach would show about 5000 rpm), but the response time was very poor (if I revved the engine from idle to WOT, the tachometer couldn't keep up with the change in rpms, it would be showing 3500 when the engine was turning 7000). I really wanted an analog tachometer, but this one just wasn't cutting it. I had dabbled very lightly in arduino-type stuff previously and thought that I could, with enough time, information, and headache medicine, make my own tachometer plus a small array of information displays like voltage, oil temp, and speed. So far, I've got a servo to move; reflecting a measured rpm signal (on the previous page). That was pretty easy compared to what I have been doing over the last few days - using a stepper motor instead of a servo. Over the last 5 or so days, I've got the stepper motor to sweep back and forth hitting both end stops and setting itself up at the initial starting position. That might not seem like a lot to get done in 5 days, but I do have ADD, so I can only work at programming for a couple hours at a time before my brain refuses to stay focused for more than 5 seconds. Also, I am learning the arduino coding language (which, as I understand it, is a modified C language) as I go, so I am constantly looking up how to do certain things and if other people have done similar things to what I am doing. |

|

Senior Clinician

Currently Offline

Posts: 212

Likes: 2

Joined: Jun 1, 2011 16:30:33 GMT -6

|

Post by cdoublejj on Apr 3, 2015 14:15:07 GMT -6

interesting i assumed the gy6 tachs on ebay would have fit the bill, guess you learning something new every day.

i think i might have project some one like you who can 3d print can do. it may be possible to raise the oil pressure for cooler with out need of an external pump by printing gears. the oil pump gear is plastic! ....ssoooo why do need a metal gear on the crank to drive it again? ...hhhhmm wonder if we could print that gear and put a dowel pin it!? more rpm on the pump and more oil! ....in theory.

|

|

Certified Clinician

Currently Offline

Posts: 59  Likes: 3

Likes: 3

Joined: Oct 23, 2014 2:02:57 GMT -6

|

Post by scooter2 on Apr 3, 2015 14:58:50 GMT -6

how cam you can just wire up a tack like one normally would instead of making your own? or is it all just for fun? For me, it's 1/3 fun, 1/3 necessity*, and 1/3 teaching my self something new. *When I was looking for a tach for my scooter, I had searched all over the internet for a smallish tach for motorcycles, ATVs, snowmobiles, and the like that wasn't digital and would work with a 4-stroke engine with wasted spark ignition (one spark per revolution) for under $50. The only one that I could find was the chrome one that I took apart on the previous page. I had the tach that I took apart previously hooked up to my scooter, and it worked like it should (meaning when the engine was turning at 5000 rpm, the tach would show about 5000 rpm), but the response time was very poor (if I revved the engine from idle to WOT, the tachometer couldn't keep up with the change in rpms, it would be showing 3500 when the engine was turning 7000). I really wanted an analog tachometer, but this one just wasn't cutting it. I had dabbled very lightly in arduino-type stuff previously and thought that I could, with enough time, information, and headache medicine, make my own tachometer plus a small array of information displays like voltage, oil temp, and speed. So far, I've got a servo to move; reflecting a measured rpm signal (on the previous page). That was pretty easy compared to what I have been doing over the last few days - using a stepper motor instead of a servo. Over the last 5 or so days, I've got the stepper motor to sweep back and forth hitting both end stops and setting itself up at the initial starting position. That might not seem like a lot to get done in 5 days, but I do have ADD, so I can only work at programming for a couple hours at a time before my brain refuses to stay focused for more than 5 seconds. Also, I am learning the arduino coding language (which, as I understand it, is a modified C language) as I go, so I am constantly looking up how to do certain things and if other people have done similar things to what I am doing. I like the cheap digital tach/hour meters on ebay. You wrap a wire around your plug wire, stick it to the dash with some velcro and you're in business. I love arduinos. I have built some far out stuff with them, and ebay is loaded with sensors and stuff for making gobs of goodies. If I may ask, why didn't you stick with the servo? It seems like a good unit for showing tach speeds and they come in a bunch of sizes. |

|

Certified Clinician

Currently Offline

Posts: 59  Likes: 3

Likes: 3

Joined: Oct 23, 2014 2:02:57 GMT -6

|

Post by scooter2 on Apr 3, 2015 15:06:24 GMT -6

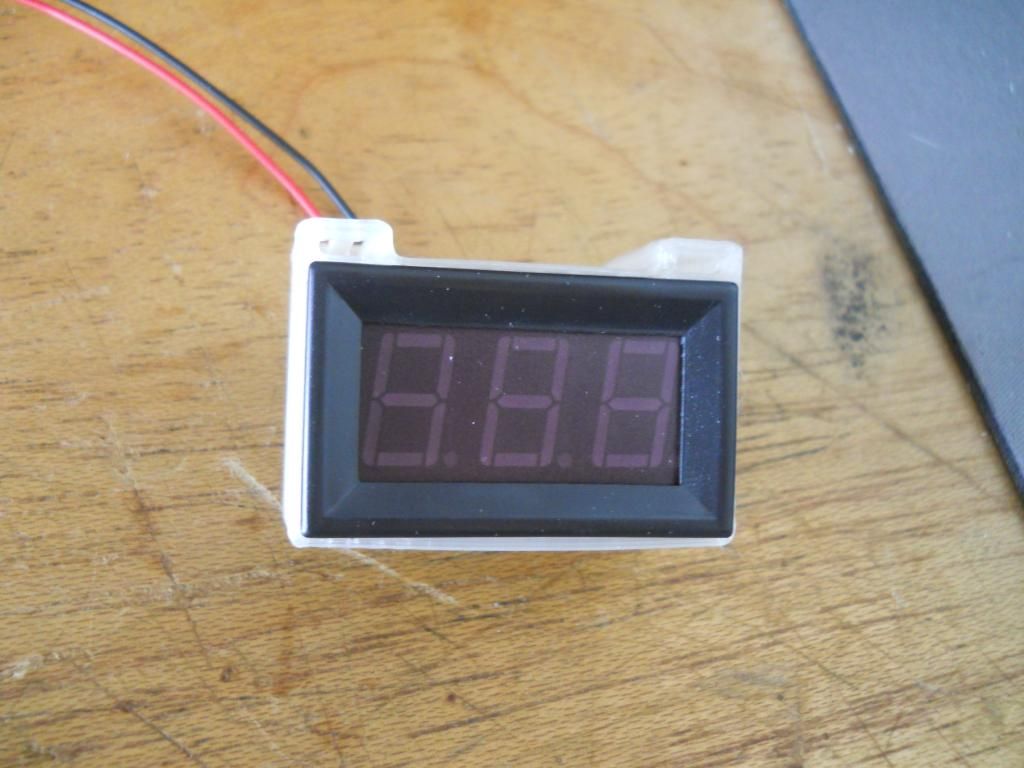

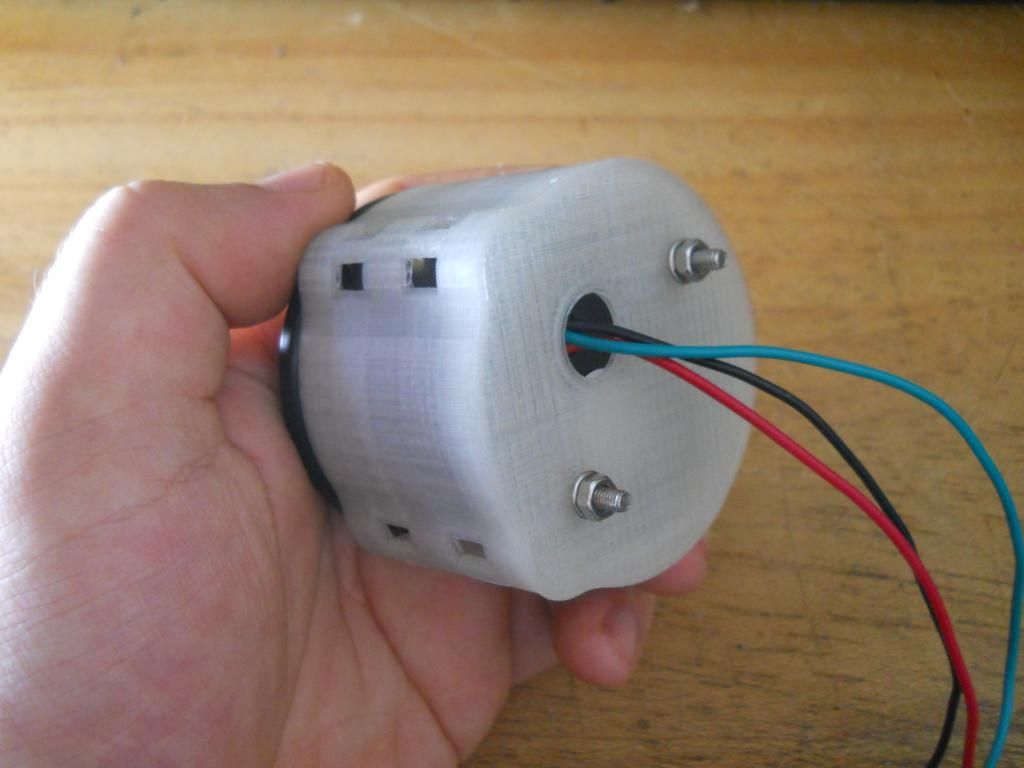

Well, no migraine yesterday but my allergies were hell. Here are the gauge holders I made yesterday for the oil temperature and voltmeter:      I plan on mounting them to the scoot with zip ties. Today I'll try and get the bicycle speedometer mounted, the oil temp and voltmeter gauges installed, and possibly go for a ride and see what kind of oil temps I get. Do you have a 3D printer? If so, what kind is it, what kind of drawing software do you use with it, and how well does it work, glitches, other problems when making parts, etc? |

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Apr 3, 2015 18:55:07 GMT -6

interesting i assumed the gy6 tachs on ebay would have fit the bill, guess you learning something new every day. i think i might have project some one like you who can 3d print can do. it may be possible to raise the oil pressure for cooler with out need of an external pump by printing gears. the oil pump gear is plastic! ....ssoooo why do need a metal gear on the crank to drive it again? ...hhhhmm wonder if we could print that gear and put a dowel pin it!? more rpm on the pump and more oil! ....in theory. The plastic that I print in, PLA, doesn't hold up to high(er) temperatures very well. In fact, If I remember correctly, you can't print a coffee cup out of it because the hot coffee will soften (not melt) the plastic enough to cause the cup to leak. Coffee is served below 100°C (212°F). I have recorded oil temps on my scooter of 115°C (239°F). I know that the gear that drives the oil pump is located outside the crankcase, but I do think that the temperatures it would see would cause it to soften enough to either start slipping on the shaft or mangle the teeth of the gear. Also, if you wanted a gear with less teeth on it and the same distance between the teeth, then logically, the gear diameter would have to be smaller. From what I can gather, the oil pump is rigidly mounted to a singe point on the side of the crankcase. If you were to put a smaller gear on the pump, the gear on the crankshaft wouldn't reach the teeth of the gear on the pump. I like the cheap digital tach/hour meters on ebay. You wrap a wire around your plug wire, stick it to the dash with some velcro and you're in business. I love arduinos. I have built some far out stuff with them, and ebay is loaded with sensors and stuff for making gobs of goodies. If I may ask, why didn't you stick with the servo? It seems like a good unit for showing tach speeds and they come in a bunch of sizes. I have one of those knockoff chinese tiny tachs as well. It works well for measuring rpms at a steady state. That is, that the response time on those is even worse than the analog tach I took apart. I would be riding my scooter, stopped at a stop sign and pull the throttle wide open and there would be about 5-7 seconds between when the engine speed plateaued and when the tach read WOT rpm's. Also, the one I have, for whatever reason, only shows 1/2 of my engine's speed, so I am always having to mentally double what I see on it. I haven't chosen between the servo and the stepper motor yet, I just want to see the difference in how they perform. Also, the servo only has 180° of movement, the stepper motor has 315°, the same as you get in your car. In fact, the stepper motors I am using are what GM uses in many of their dashboards. I six stepper motors, but they each need a driver board and I only have one of those. I have two servos and those don't need any driver boards. Do you have a 3D printer? If so, what kind is it, what kind of drawing software do you use with it, and how well does it work, glitches, other problems when making parts, etc? I do have a 3d printer. It is a PrintrBot Jr. V1. It isn't being made anymore, the closest they are making to what I have is the PrintrBot Simple Maker's Kit for $349. It is actually cheaper than the printer that I bought. If you want to step up to a metal-framed printer, they have the PrintrBot Simple Metal Kit for $539. Both require assembly, as did mine, but oh man, it was like I was 8 years old playing with legos when I put together my printer. And if you are wondering, no I am not sponsored by Printrbot, I just like to spread the word of great companies, especially ones that started from essentially nothing (Printrbot started a few years ago from a kickstarter project!) As for drawing software, I have 123D Design (free), SketchUp 8/2013/2014 (free), Blender (free), FreeCAD (free), Inventor 2012 (not free), and AutoCAD 2010 (not free) installed, but I mainly use Inventor because I took 4 years of drafting classes in high school, 2 of those with AutoCAD and 2 with Inventor, so I know how to use them quite well. As for how it performs, It met, if not exceeded all of my expectations. There were and still are a few things that I could do to make it better and a few things I had to do to it to make it function properly, but honestly, I expected that from this machine. One great think about 3d printers is that you can design your own and/or download upgrades and replacement parts and print them yourself! As far as glitches go, I have only really encountered one real firmware glitch on the mainboard that controls the printer. The mainboard uses a microSD card as storage for the files that it needs to print objects. I may have removed the SD card without properly ejecting it once, and subsequently the printer would not read any of the files on the card, it just gave an error code. I could still put the card in a card reader on my pc and see all of the files just fine. I formatted the card and put all of the files back on it and it worked again. One of the larger problems I've had hardware-wise that happened mid-print was the pulleys coming loose on the stepper motor's shaft causeing one of the axes to stop moving. I fixed that with some blue locktite. I typed up a review/overview/explanation here on how you go from idea to drawing to slicing to printing. I haven't been using the printer too much lately, I've been working on the arduino stuff or playing with another idea I have that is quite similar to a printer. (Hint: lasers!) |

|

|

|

Post by cyborg on Apr 3, 2015 21:36:00 GMT -6

I see a junk yard motorcycle tach in your future,,, even a blemished one,,, you could just go for the guts and hybridize the face of a smaller scooter one with one of your sweet cases you make

|

|

Certified Clinician

Currently Offline

Posts: 59  Likes: 3

Likes: 3

Joined: Oct 23, 2014 2:02:57 GMT -6

|

Post by scooter2 on Apr 4, 2015 0:45:11 GMT -6

Thanks for the reply and the link. My tachs work fine with little delay. Some have settings you can change to switch from two cycle to four cycle so you get the proper readout. On servos, you can use a winch type that can go round and round forever. Maybe we can collaborate on an arduino project some time. That would be fun. These cheap tachs are less than $15 on ebay. Pressing the S1 button switches the tach from one fire per rev, two fires per rev, and every other rev, so it works with 2 strokes and 4 strokes. Also has an hour meter and can be set to alert you for, say, an oil change at X hours. It does not have a backlight so it's not so useful in the dark. I think the built in battery runs for two years.  |

|

Senior Clinician

Currently Offline

Posts: 212

Likes: 2

Joined: Jun 1, 2011 16:30:33 GMT -6

|

Post by cdoublejj on Apr 4, 2015 2:47:24 GMT -6

interesting i assumed the gy6 tachs on ebay would have fit the bill, guess you learning something new every day. i think i might have project some one like you who can 3d print can do. it may be possible to raise the oil pressure for cooler with out need of an external pump by printing gears. the oil pump gear is plastic! ....ssoooo why do need a metal gear on the crank to drive it again? ...hhhhmm wonder if we could print that gear and put a dowel pin it!? more rpm on the pump and more oil! ....in theory. The plastic that I print in, PLA, doesn't hold up to high(er) temperatures very well. In fact, If I remember correctly, you can't print a coffee cup out of it because the hot coffee will soften (not melt) the plastic enough to cause the cup to leak. Coffee is served below 100°C (212°F). I have recorded oil temps on my scooter of 115°C (239°F). I know that the gear that drives the oil pump is located outside the crankcase, but I do think that the temperatures it would see would cause it to soften enough to either start slipping on the shaft or mangle the teeth of the gear. Also, if you wanted a gear with less teeth on it and the same distance between the teeth, then logically, the gear diameter would have to be smaller. From what I can gather, the oil pump is rigidly mounted to a singe point on the side of the crankcase. If you were to put a smaller gear on the pump, the gear on the crankshaft wouldn't reach the teeth of the gear on the pump. I like the cheap digital tach/hour meters on ebay. You wrap a wire around your plug wire, stick it to the dash with some velcro and you're in business. I love arduinos. I have built some far out stuff with them, and ebay is loaded with sensors and stuff for making gobs of goodies. If I may ask, why didn't you stick with the servo? It seems like a good unit for showing tach speeds and they come in a bunch of sizes. I have one of those knockoff chinese tiny tachs as well. It works well for measuring rpms at a steady state. That is, that the response time on those is even worse than the analog tach I took apart. I would be riding my scooter, stopped at a stop sign and pull the throttle wide open and there would be about 5-7 seconds between when the engine speed plateaued and when the tach read WOT rpm's. Also, the one I have, for whatever reason, only shows 1/2 of my engine's speed, so I am always having to mentally double what I see on it. I haven't chosen between the servo and the stepper motor yet, I just want to see the difference in how they perform. Also, the servo only has 180° of movement, the stepper motor has 315°, the same as you get in your car. In fact, the stepper motors I am using are what GM uses in many of their dashboards. I six stepper motors, but they each need a driver board and I only have one of those. I have two servos and those don't need any driver boards. Do you have a 3D printer? If so, what kind is it, what kind of drawing software do you use with it, and how well does it work, glitches, other problems when making parts, etc? I do have a 3d printer. It is a PrintrBot Jr. V1. It isn't being made anymore, the closest they are making to what I have is the PrintrBot Simple Maker's Kit for $349. It is actually cheaper than the printer that I bought. If you want to step up to a metal-framed printer, they have the PrintrBot Simple Metal Kit for $539. Both require assembly, as did mine, but oh man, it was like I was 8 years old playing with legos when I put together my printer. And if you are wondering, no I am not sponsored by Printrbot, I just like to spread the word of great companies, especially ones that started from essentially nothing (Printrbot started a few years ago from a kickstarter project!) As for drawing software, I have 123D Design (free), SketchUp 8/2013/2014 (free), Blender (free), FreeCAD (free), Inventor 2012 (not free), and AutoCAD 2010 (not free) installed, but I mainly use Inventor because I took 4 years of drafting classes in high school, 2 of those with AutoCAD and 2 with Inventor, so I know how to use them quite well. As for how it performs, It met, if not exceeded all of my expectations. There were and still are a few things that I could do to make it better and a few things I had to do to it to make it function properly, but honestly, I expected that from this machine. One great think about 3d printers is that you can design your own and/or download upgrades and replacement parts and print them yourself! As far as glitches go, I have only really encountered one real firmware glitch on the mainboard that controls the printer. The mainboard uses a microSD card as storage for the files that it needs to print objects. I may have removed the SD card without properly ejecting it once, and subsequently the printer would not read any of the files on the card, it just gave an error code. I could still put the card in a card reader on my pc and see all of the files just fine. I formatted the card and put all of the files back on it and it worked again. One of the larger problems I've had hardware-wise that happened mid-print was the pulleys coming loose on the stepper motor's shaft causeing one of the axes to stop moving. I fixed that with some blue locktite. I typed up a review/overview/explanation here on how you go from idea to drawing to slicing to printing. I haven't been using the printer too much lately, I've been working on the arduino stuff or playing with another idea I have that is quite similar to a printer. (Hint: lasers!) hence why you have to have bigger crank shaft gear (press on) to match the now small pump gear. well if higher temp plastic exists it seems plausible. this guy tested out some super rough unfinished gears at 4200 RPM. |

|

Doc's Anything Goes

Currently Offline

Posts: 371  Likes: 18

Likes: 18

Joined: Jun 13, 2014 16:48:23 GMT -6

|

Post by glavey on Apr 4, 2015 8:25:48 GMT -6

Personally, I just wouldn't trust a printed gear on something as mission-critical as an oil pump. I'll stick with the injection molded plastic gear that is on there now.

|

|

|

|

Post by cyborg on Apr 4, 2015 9:12:28 GMT -6

I second that a printed gear will not stand up to the heat of engine oil

|

|

Certified Clinician

Currently Offline

Posts: 59  Likes: 3

Likes: 3

Joined: Oct 23, 2014 2:02:57 GMT -6

|

Post by scooter2 on Apr 4, 2015 9:42:06 GMT -6

I second that a printed gear will not stand up to the heat of engine oil If his machine can do it, he could try nylon with a melting point of 428F or nylon 6,6 which melts at 509F. On my 150 my oil temps read, with a cheap thermometer, around 200 degrees as I recall. |

|

|

|

Post by cyborg on Apr 4, 2015 10:14:39 GMT -6

oh i agree if his printer can go that high,,,doubt it but if it can it's possible,,,or at least make a gear that a mold can be taken off of

|

|

Certified Clinician

Currently Offline

Posts: 59  Likes: 3

Likes: 3

Joined: Oct 23, 2014 2:02:57 GMT -6

|

Post by scooter2 on Apr 4, 2015 10:39:14 GMT -6

oh i agree if his printer can go that high,,,doubt it but if it can it's possible,,,or at least make a gear that a mold can be taken off of Yes. It depends on the printer. I really want one. I just need to figure out why, so I can have an excuse to buy one.  |

|