|

|

Post by royldoc on Jul 6, 2011 11:57:31 GMT -6

Man, I knew I shoulda put my 350 in the maggi. I can make it fit to. I got a B.M.F.H. and a 9/16 blue flame wrench. ;D

Roy

|

|

|

|

Post by royldoc on Jul 4, 2011 16:56:09 GMT -6

I don't have any photo's either. The fifty's mount different than the 150's. It's a pain to take all the plastic off . I will take photo's next time I do.

Roy

|

|

|

|

Post by royldoc on Jul 4, 2011 16:20:42 GMT -6

Lets not forget what the true meaning of Independence day means.

I'm going to thank the founders of the Constitution and the people who fought and died for our liberty and freedom.

Roy

|

|

|

|

Post by royldoc on Jul 2, 2011 16:45:09 GMT -6

I think there is more to this. Why did he run after he wrecked? Still it is a hard way to go down.

Roy

|

|

|

|

Post by royldoc on Jun 28, 2011 12:00:51 GMT -6

How about this. Many people just read the posts without signing on. They absorb the information in stealth and nobody knows. Does this still bother you? I did for many weeks before I joined.

I'm sorry Luke but I have to disagree with you on the gun thing. I'm pro- second amendment. I am going to leave it at that.

When I first got a scooter I didn't know much about them. Thanks to all the wise and information generous people of this forum and others I will not mention I learned a great deal.

Thank You All.

Roy

|

|

|

|

Post by royldoc on Jun 27, 2011 10:27:14 GMT -6

Many people have asked me "Is that a Pontiac?"  I just tell them "It's a Chinese Cadillac." Roy |

|

|

|

Post by royldoc on Jun 24, 2011 8:14:28 GMT -6

Alley,

I can't weld very good. Set screws will be easy. I would rather use a thrust bearing, they will last longer than a floating ring. The thrust bearing is only about $15.00.

Roy

|

|

|

|

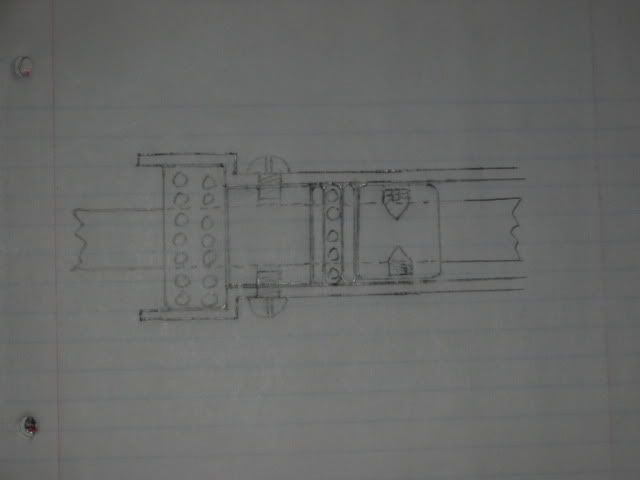

Post by royldoc on Jun 24, 2011 0:22:45 GMT -6

Here is the drawing.  Roy |

|

|

|

Post by royldoc on Jun 23, 2011 23:06:54 GMT -6

Alley, I know it only needs one side. I'm thinking I might just move the collar that is screwed to the tube against the large outer bearing.

Roy

|

|

|

|

Post by royldoc on Jun 23, 2011 12:13:10 GMT -6

I'm having a hard time locating the thrust bearings I want. I found some that are close but slightly large on the o.d. and small on i.d.. The bearing is a metric BHTASYM2844 28mm bore x 44mm o.d. x 10.86mm thick. The other is inch BHTASY-112 1.125" bore x 1.750" o.d. x .427" thick. These are ball roller bearings. they are out of stock on both. I might have to use needle roller bearings but don't want to. I will have to bore the tube out to either 1.750" or 44mm and turn the axle down to 1.125" or 28mm depending on which bearing I can get.

Roy

|

|

|

|

Post by royldoc on Jun 23, 2011 9:09:31 GMT -6

Here is a crude drawing of my idea.  I will drill holes in the center collar for grease channels and add a grease zerk, so bearings can be greased. Roy |

|

|

|

Post by royldoc on Jun 22, 2011 11:53:11 GMT -6

Just got done doing a little research. The original bearing is a NSK 6205Z the z means it has metal shields. The rs means it has rubber seals. The I.D is 25mm the O.D is 52mm and width is 15mm. The bearing I got now don't have any seals but will work till I order new ones. The width is 20.6 mm. the thickness of ring and shim is 5.04mm, so I may not have to bore the tube.

Roy

|

|

|

|

Post by royldoc on Jun 21, 2011 23:28:36 GMT -6

I forgot to mention the original bearing is a NSK brand #6205Z. The bearing I'm going to use is a GBC brand #5205.

Roy

|

|

|

|

Post by royldoc on Jun 21, 2011 23:21:11 GMT -6

I pressed the bearing off the axle today at work. the ring behind the bearing is not part of the axle, it appeared to be the race from a thrust bearing and it had a thin shim washer between it and the bearing.  I think I found a good way. I measured the thickness of bearing, shim washer and ring. it was .795". I found a bearing that is just a little thicker .814" with the proper i.d an o.d. I will have to bore the axle tube about .020" deeper to get the c clip in with the thicker bearing. but the outside race of the bearing will rest on the smaller tube and wont spin to wear it out any more. As far as dimpling shaft not a problem, I have special bits made to drill through hardened steel. These drill bits are made to drill through safe doors and will drill through a hardened ball bearing no problem. Now I just have to find the right thrust bearings and get a couple of collars. Roy |

|

|

|

Post by royldoc on Jun 21, 2011 11:30:49 GMT -6

Ya, it does need some grease. I'm thinking about putting a collar and a thrust bearing on the other end of axle. The thrust bearing will go between differential plate and collar on shaft. What ya think?

Roy

|

|